Infectious microorganisms like bacteria, viruses, fungal spores, and sometimes parasites are found to contaminate the food and beverage factories constantly. These harmful microbes are infecting either the product or the factory surfaces and equipment. Important fomites include,

- Food processing machines

- Tools and handles

- Enclosed regions like chambers, towers, or labs

- Packaging containers

- Filling equipment

- Conveyor belts and processors

- Finished product surfaces

- Meat processing bays

- Tubes, foils, and films

This shows a huge probability of contaminations, and thus disinfection becomes indispensable at every stage of a food or beverage factory, making it a routine.

How does UVC disinfection work?

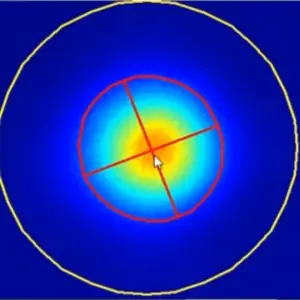

UVC light, when exposed to microorganisms, penetrates their cells and stimulates thymine-involved nucleic acid changes, making them ineligible to replicate or multiply further. This either results in killing or complete inactivation of the microbial cells.

Also, from research studies, it is clear that the UVC disinfection works exponentially. The higher the exposure, the higher is the effectiveness of disinfection.

The food manufacturing industry-standard levels of UVC range between 10 to 100 mJ/cm2.

US FDA Recommendations

The US Food and Drug Administration, along with the Department of Health and Human Services, has given a set of recommendations for using UVC as a potential and safe disinfection system in the food industry during food processing and treatment.

Some of the recommendations include,

- A low-pressure mercury lamp is considered safe when 90% of the emission radiates at a wavelength of 253.7 nanometers.

- Radiation up to a depth of 1 cm or less for water.

- For high-fat food, surface radiation at 1W is permitted.

Advantages of UV disinfection over other methods

- Eliminates 99.99% of the contaminations at high doses

- Does not cause any physicochemical changes to the food or baked product as it is a non-thermal process

- A safe, economic, and one-time investment

- No laborious installation

- Potential against almost all types of food-borne microbes like yeasts, spores, molds, bacteria, and viruses

Ultraviolet Light DisinfectionWhat should you consider before buying a UVC disinfection system?

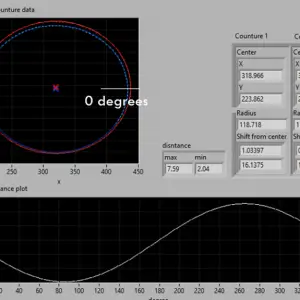

Not all UV light disinfection systems work on all microbial matters. The effectiveness in disinfection broadly depends upon,

- The cell wall of the target microorganisms (Example: Bacteria like E.Coli and Salmonella have thin cell membranes, whereas mold spores have thick walls)

- The dose of the UVC light

- Target count of the microbes

- Prevalence of reflective surfaces

- Temperature, humidity, and moisture content

Therefore, consider all the above factors before buying a UVC disinfection system for your food processing plant. However, specialized products in the market like PXL Sanitizers that have proven to work effectively in a food or beverage factory shall be given high preferences when purchasing.

Implementation in Food Factories

From a small kitchen to top food factories, there have been UV light disinfection units installed. Some companies may have fitted UV reflectors, yet might be facing microbial contaminations due to improper maintenance or wrong usage.

Hence, deploying the right UV equipment with sufficient intensity and dose in the right positions and volumes in the required surface/environment only can refrain a food and beverage company from being contaminated.