Introduction to Integrating Sphere

An integrating sphere is a critical tool in optical measurements, especially for characterizing light sources such as LEDs. Its design and functionality are rooted in fundamental principles of optics and photometry. This article delves into the intricacies of integrating spheres, their design, operational principles, and their role in LED inspection.

Design and Working Principle of Integrating Sphere:

An integrating sphere is a hollow spherical cavity with its inner surface coated with a highly reflective diffuse coating. Common materials for this coating include barium sulfate (reflectivity > 98%) and polytetrafluoroethylene (PTFE) (reflectivity > 99%), which provide near-Lambertian reflectance. The sphere has several ports, or openings, for the entry and exit of light and for mounting detectors and light sources. The ports are typically arranged to minimize direct light paths between them, ensuring multiple reflections within the sphere.

Working Principle:

When a light source, such as an LED, is placed in or directed into the integrating sphere, the light is scattered uniformly across the inner surface due to the diffuse coating. This scattering process ensures that the light is homogenized, effectively removing any spatial variations and providing a uniform distribution of light within the sphere. The uniform light distribution is then measured by detectors placed at specific ports on the sphere.

The physics behind the integrating sphere involves multiple reflections of light off the inner surface, leading to a uniform light field. This is governed by Lambert’s cosine law, which states that the intensity of light reflected off a diffuse surface is directly proportional to the cosine of the angle between the incident light and the surface normal.

\( I = I_0 \cos(\theta) \)

where \( I \) is the intensity of reflected light, \( I_0 \) is the intensity of incident light, and \( \theta \) is the angle of incidence.

Measurements with Integrating Sphere

Integrating spheres can measure various quantities related to light sources, including:

1. Radiance: The measure of the amount of light that passes through or is emitted from a particular area and falls within a given solid angle.

\( L = \frac{d^2\Phi}{dA \cdot d\Omega \cdot \cos(\theta)} \)

2. Irradiance: The measure of the power of electromagnetic radiation per unit area incident on a surface.

\( E = \frac{d\Phi}{dA} \)

3. Radiant Intensity: The amount of radiative power emitted by a source in a particular direction per unit solid angle.

\( I = \frac{d\Phi}{d\Omega} \)

4. Color Temperature: The temperature at which a black body would emit radiation of the same color as the light source.

5. Spectral Power Distribution (SPD): The measure of the power per unit area per unit wavelength of the light emitted by the source.

Characterizing Light Sources:

Integrating spheres are particularly useful for characterizing light sources like LEDs because they can measure the total luminous flux, spectral power distribution, and color temperature. By capturing all the light emitted by the LED, including light emitted in all directions, the integrating sphere provides accurate and comprehensive data.

Applications:

Integrating spheres can be used for various light sources, including LEDs, lasers, and incandescent bulbs. They are essential in industries where precise light measurements are critical, such as in display technology, automotive lighting, and architectural lighting.

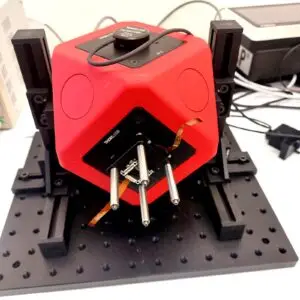

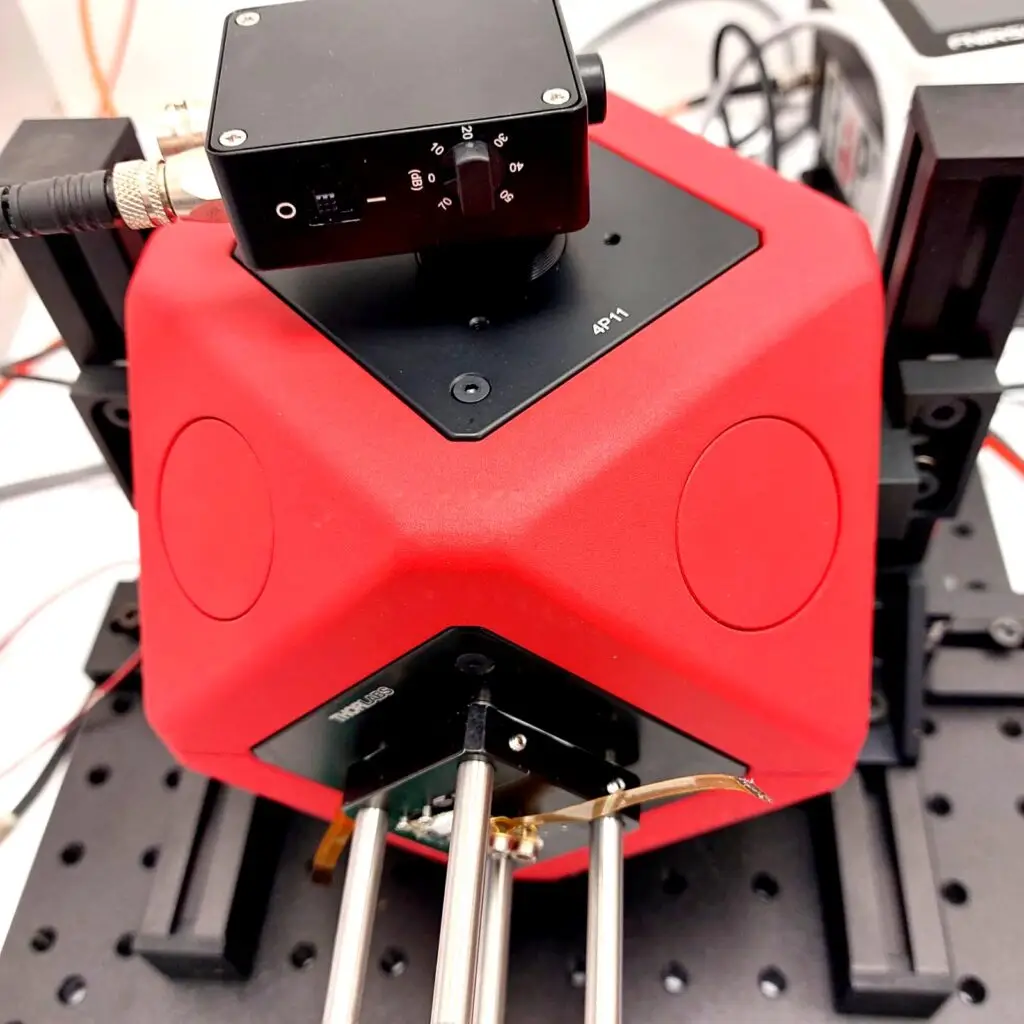

Case Study: Integrating Sphere for Bare LED Measurement by IZAK Scientific

IZAK Scientific recently developed an bare LED inspection system based on integrating sphere. This custom integrating sphere features multiple channels for comprehensive LED characterization:

1. LED Power Measurement: One channel is dedicated to measuring the total power output of the LED. This involves capturing all the emitted light and providing an accurate measure of the LED’s luminous flux. The power measurement is performed using a calibrated precision power meter.

2. Spectrum Measurement: Another channel is equipped with a high-resolution spectrometer to measure the spectral power distribution. This allows for detailed analysis of the LED’s color properties and helps in determining the color temperature. The spectrometer is calibrated to account for the sphere’s spectral reflectance properties.

3. Temporal Pulse Shape Measurement: The third channel is designed to capture the temporal characteristics of the LED’s emission, providing insights into the LED’s performance over time and its response to pulsed driving currents at different repetition rate. This is achieved using a fast photodiode and an oscilloscope, capable of capturing rapid changes in the LED’s output.

Optomechanical Design:

In this project, IZAK Scientific also provided the necessary optomechanical design and implementation to hold the LED board in the correct position within the integrating sphere. This ensured that the measurements were consistent and reliable. The design included adjustable mounts to position the LED precisely at the sphere’s center and ensure optimal alignment with the measurement channels.

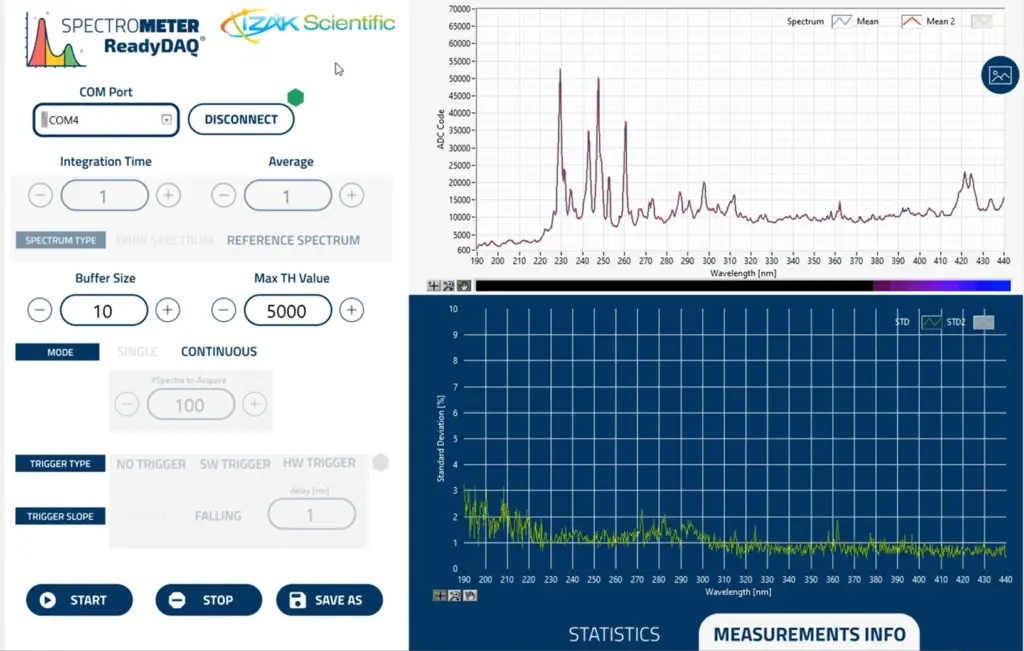

Software Application for LED Inspection System

The LED inspection system developed by IZAK Scientific includes a robust software application designed to facilitate various measurement tasks. This software supports spectrum acquisitions, power meter acquisition, and temporal shape acquisition. One of the standout features is its ability to calculate and display the number of photons per wavelength, providing a deeper insight into the LED’s performance characteristics.

The software also logs all measurement results and generates comprehensive inspection reports based on predefined Pass/Fail criteria. These criteria can include parameters such as spectrum width, energy per pulse, degradation over time, and more. The application is designed to be highly customizable, allowing it to be tailored to meet specific customer requirements. Whether it’s adjusting the pass/fail thresholds or integrating additional measurement capabilities, the software ensures flexibility and precision in LED inspection.

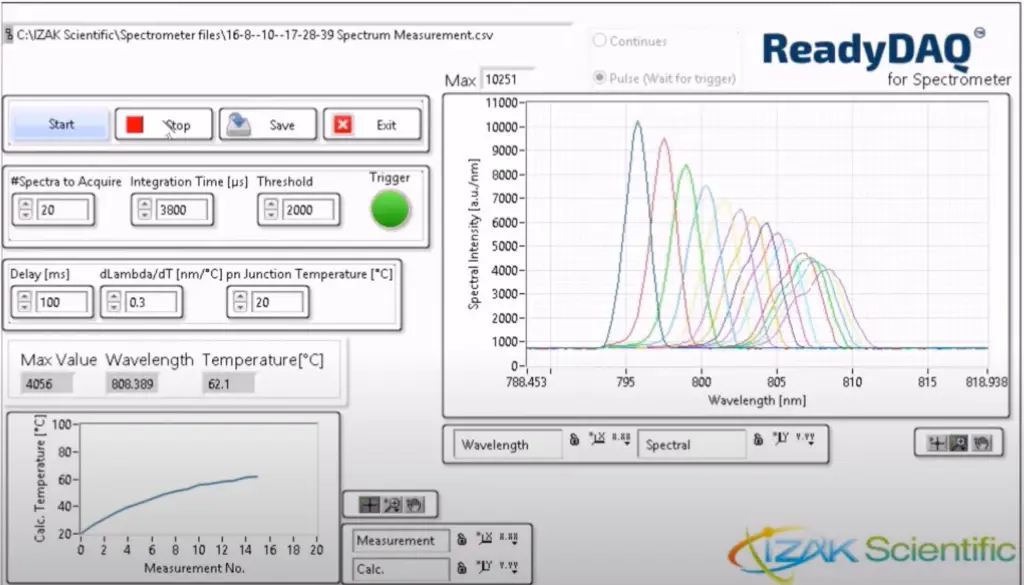

Software Application for LED Inspection System

The LED inspection system developed by IZAK Scientific includes a robust software application designed to facilitate various measurement tasks. This software supports spectrum acquisitions, power meter acquisition, and temporal shape acquisition. One of the standout features is its ability to calculate and display the number of photons per wavelength, providing a deeper insight into the LED’s performance characteristics.

Additionally, the software can calculate the pn-junction temperature, a crucial parameter often used for laser diode inspection but also highly relevant for LEDs. The pn-junction temperature is a critical indicator of the thermal performance of the LED or laser diode and can significantly impact its efficiency and lifespan.

In the provided image, one can observe a sequence of pulses that were acquired along with the calculated pn-junction temperature of the laser diode during the operation process, while the assembly is cooled. This type of measurement is essential in LED inspection as it provides valuable data regarding the LED’s or laser diode’s expected performance and lifetime.

The software also logs all measurement results and generates comprehensive inspection reports based on predefined Pass/Fail criteria. These criteria can include parameters such as spectrum width, energy per pulse, degradation over time, and more. The application is designed to be highly customizable, allowing it to be tailored to meet specific customer requirements. Whether it’s adjusting the pass/fail thresholds or integrating additional measurement capabilities, the software ensures flexibility and precision in LED inspection.

This combination of advanced measurement capabilities and detailed reporting makes IZAK Scientific’s software an invaluable tool for ensuring the quality and reliability of LEDs and laser diodes.

Conclusion

Integrating spheres are indispensable tools for LED inspection, offering a comprehensive method for measuring various optical properties. For those needing precise LED inspection tools, IZAK Scientific provides tailored solutions, including integrating spheres designed to meet specific requirements. Contact IZAK Scientific to learn more about selecting and customizing the right integrating sphere for your LED inspection needs.

If you need advanced LED inspection tools, IZAK Scientific can help you choose and design the right inspection system and define and perform customizations. Our expertise ensures you get the appropriate inspection devices coupled with or without integrating sphere based on your specific LED requirements. Contact us today to enhance your LED inspection capabilities.

Tzachi Sabati

CEO, IZAK Scientific

Physicist specializing in photonics and quantum technologies, with deep expertise in quantum sensors and advanced optical systems. Leads the Advanced Quantum Lab course at the Technion, bridging academic excellence with industry innovation. At IZAK Scientific, provides cutting-edge photonics-based solutions, developing customized inspection and sensing systems for R&D and production. Passionate about advancing quantum sensing applications and integrating novel technologies to meet industry needs.