Photonics, the intricate science of light, stands at the forefront of innovation in modern technologies. It encompasses everything from the fiber optics driving our telecommunications to the precision instruments revolutionizing medical diagnostics. Central to these advancements is the sophisticated art of photonics testing, which now integrates traditional methods with the nuanced complexities of interferometry and quantum interferometry. This amalgamation enhances the precision and accuracy of measuring light’s properties, making it a cornerstone of technological development and breakthroughs. As we delve into the realms of interferometry and quantum interferometry, we unlock new dimensions in photonics testing, ensuring the meticulous manipulation and measurement of light that is essential across various high-tech applications.

Interferometry Testing: The Precision of Light Interference in Photonics

Interferometry is a critical technique in the field of photonics, particularly renowned for its ability to measure optical properties with exceptional precision and accuracy. At its core, interferometry involves the phenomenon of interference of light waves, which is used to glean detailed information about various optical elements and systems.

The significance of interferometry lies in its ability to measure with unparalleled detail properties such as wavefront shape, surface topography, and refractive index variations. These measurements are crucial in a wide range of applications, from the calibration of high-precision optical components to the testing of lenses used in telescopes and microscopes.

How Interferometry Works

Interferometry works on the principle of superposition, where two or more light waves are overlapped, resulting in a new wave pattern. This new pattern is the result of the interference of the light waves, and it contains valuable information about the properties of the light waves themselves.

In a typical interferometric setup, a beam of coherent light, usually from a laser, is split into two paths: a reference path and a sample path. The light in the reference path travels a known distance, while the light in the sample path interacts with the object or surface being measured.

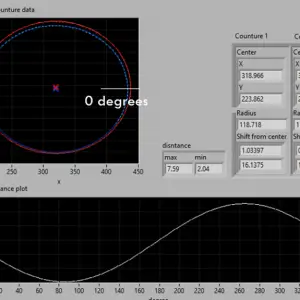

When the two beams are recombined, they interfere with each other. The nature of this interference – constructive or destructive – depends on the difference in the path lengths they traveled. Constructive interference occurs when the path length differences are multiples of the light’s wavelength, resulting in bright fringes, whereas destructive interference occurs at half-wavelength differences, producing dark fringes.

These interference patterns are captured and analyzed, typically by an imaging system. By analyzing these patterns, precise measurements can be made. For instance, any deviations in the wavefront shape of the light due to the sample can be detected as changes in the interference pattern. Similarly, variations in surface topography or refractive index will alter the path length of the sample beam, leading to observable changes in the interference fringes.

The precision of interferometry comes from its sensitivity to extremely small path length differences – often as small as a fraction of the wavelength of light used. This makes interferometry an invaluable tool in the realm of photonics, where accurate measurements of optical properties are crucial for both research and industrial applications.

Diverse Applications of Interferometry in Photonics Testing

Interferometry, with its high precision and sensitivity, finds diverse applications across various fields, particularly in photonics testing. Its ability to measure minute differences and changes in optical properties makes it an indispensable tool in several industries.

1. Telecommunications: In the field of telecommunications, particularly in fiber optics, interferometry is used to test and ensure the quality of optical fibers. These tests include measuring the uniformity of the fiber’s core diameter and detecting any imperfections or irregularities that could affect signal transmission. In addition, interferometry is used to calibrate and align optical components within communication systems, ensuring optimal performance.

2. Precision Engineering: Interferometry plays a critical role in precision engineering, especially in the manufacturing of components with extremely tight tolerances. It is used to measure the flatness and surface quality of precision-engineered components such as semiconductor wafers, mirrors, and lenses. This ensures that these components meet stringent specifications and perform as expected in their respective applications.

3. Astronomy: In astronomy, interferometry is used to enhance the resolution of telescopes. By combining the light collected from multiple telescopes, astronomers can create an “interferometer” that effectively acts as a telescope with a much larger aperture. This technique allows for the observation of celestial bodies with much greater detail and resolution than could be achieved with a single telescope.

Quantum Interferometry in Testing and Measurement Applications

Quantum interferometry, leveraging the unique properties of quantum mechanics, has ushered in a new era in testing and measurement technologies. By employing particles in a quantum state, such as entangled photons or atoms, quantum interferometers can detect and measure with unparalleled precision. This capability is especially beneficial in environments where traditional testing methods fall short due to sensitivity limitations or external disturbances. In practical applications, quantum interferometry can be used to create highly sensitive sensors for detecting minute gravitational variations, which is crucial in geology for underground structure analysis or in navigation systems. Additionally, in the field of material science, it allows for the observation of quantum effects in various materials, providing insights that are essential for the development of new quantum technologies, including quantum computing and secure quantum communication systems. The extreme sensitivity of quantum interferometry makes it a potent tool in advancing precision in various scientific and industrial testing applications.

Examples of Interferometry in Quality Control and Calibration

1. Quality Control of Optical Components: Interferometry is extensively used in the quality control of lenses, mirrors, and other optical components. For example, in lens manufacturing, interferometry is used to ensure that the curvature of the lenses is precisely as designed. This is crucial for applications ranging from eyewear to high-end optical instruments.

2. Calibration of Measurement Instruments: Many optical measurement instruments rely on components that must be calibrated to ensure accuracy. Interferometers are used to calibrate devices like autocollimators and angle measurement systems, which are essential in fields that require high-precision angle measurements, such as in the alignment of machine tools.

3. Surface Topography Analysis: Interferometry is key in analyzing the surface topography of materials in nanotechnology and materials science. It can detect surface imperfections at the nanometer scale, which is vital for applications where surface smoothness is critical, such as in the manufacturing of hard drive components or optical coatings.

4. Wavefront Analysis for Adaptive Optics: In systems like adaptive optics, which are used to correct distortions in telescopic images caused by the Earth’s atmosphere, interferometry is used to analyze and correct the wavefronts of light. This allows for much clearer images in both astronomical and military applications.

These applications highlight the versatility and indispensability of interferometry in photonics testing. Its ability to provide accurate and detailed measurements is crucial in ensuring the quality and performance of a wide range of optical components and systems across various industries.

Challenges in Photonics Testing

Photonics testing faces challenges such as environmental sensitivity, the need for high accuracy, and dealing with a wide range of light wavelengths. IZAK Scientific’s solutions are designed to overcome these challenges, offering robust and reliable measurements even in demanding conditions. Their equipment can accurately measure light across a broad spectrum, from ultraviolet to infrared, ensuring comprehensive testing capabilities.

Customization and Adaptation in Photonics Testers

Customization is crucial in photonics testing due to the varied nature of applications. IZAK Scientific recognizes this need and offers customizable solutions to cater to specific industrial requirements. This adaptability ensures that clients receive testers that are tailored to their unique needs, enhancing the efficiency and effectiveness of their technological applications.

Future Trends in Photonics Testing and Measurement

The future of photonics testing looks promising, with trends pointing towards further miniaturization, integration of AI for enhanced data analysis, and the development of more user-friendly interfaces. These advancements will not only make photonics testing more accessible but also expand its applications into new and emerging fields.

Conclusion: The Impact of Accurate Photonics Testing

Accurate photonics testing is integral to the advancement of technologies that rely on light. The precision and reliability of these tests are paramount, and IZAK Scientific’s commitment to innovation in this field ensures that their clients are at the cutting edge of technological progress. As we continue to explore the potential of light in technology, the role of photonics testers will only become more vital.