For any food and related products, hygiene plays a vital role. Thus, the packaging step in a food or a beverage factory is highly critical to curbing microbial contamination. Any infection or contamination may lead to the reduced shelf-life of the food product and, in turn, pull down the industry’s sales and revenue.

To maintain quality packaging, UV irradiation is chosen to be one of the effective and economical means to disinfect the packaging materials that do not deteriorate the food and product quality. Luckily, it is proven that food-borne microbes like E.coli and Salmonella are easily destroyed with the UV disinfection method.

Another crucial factor to consider in the food industry is that the food products can easily get infected from microbes on the container surfaces, air chambers, and cooling towers. The use of chemical or other disinfection methods to destroy such microbes may mostly affect food products. The UV disinfection method is found to be a cool and easy method to cleanse food processing zones.

Why UVC for Packaging?

The UV radiation has bactericidal and fungicidal abilities that help irradiate the food packaging materials without bringing any change or damage to the food directly.

By disinfecting the packaging materials or the whole packaging process in the food industry, any microbes, if suspended in the air, are destroyed, and the surfaces, air, or particles that are going to interact with the food product are cleaned.

Advantages of using UVC over chemical or thermal disinfection methods include,

- Fast and reliable

- Safe and simple

- Energy efficient

- One-time installation

- Long-lasting service

- Easy retrofitting

- Low maintenance costs

Proven example: Post numerous researches, UV light disinfection has been employed in many milk industries to disinfect the acidic milk packaging materials (Yoghurt filler, Kefir packing, sealing machines, cups, caps, tubes, the neck of the bottles, sachets, etc.). This method also avoids the use of chemical disinfectants.

UV light disinfection method is highly beneficial when used to disinfect paste-like or liquid-based food products.

The Potential of UVC Light for Packaging Disinfection

Using UVC in the food industry depends on two important factors:

- The UV radiation dose required to kill the target microorganisms depends on the cell wall and the structure. For example, bacteria, such as Salmonella and E.coli, possess a thin-layered cell wall and can be destroyed with a slight dose. However, vulnerable microbes, such as spores, possess thick cell walls and try to protect themselves against UV radiation if the adequate dose is not provided.

- Combining UV radiation with hydrogen peroxide is found to reduce the germs by up to 99.99%.

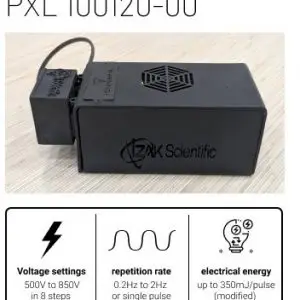

PXL Sanitizer and Packaging Units

Based on the empirical evidence and scientific studies, pulsed UV light technology has been promising to disinfect food and packaging surfaces when ultra-short pulses of UVC emission in the range of 200-280 nm are applied. PXL sanitizer is renowned for pulsed UVC emissions, and these portable sanitizers and industrial UV chambers are tested and authenticated.

Tzachi Sabati

CEO, IZAK Scientific

Physicist specializing in photonics and quantum technologies, with deep expertise in quantum sensors and advanced optical systems. Leads the Advanced Quantum Lab course at the Technion, bridging academic excellence with industry innovation. At IZAK Scientific, provides cutting-edge photonics-based solutions, developing customized inspection and sensing systems for R&D and production. Passionate about advancing quantum sensing applications and integrating novel technologies to meet industry needs.