The pharmaceutical industry and specifically pharmaceutical production, has been following strict standards with regards to quality. Water being the largest volume of material consumed by the pharmaceutical production companies, more than the international regulatory standards, the company per se practices enormous internal water standards and norms. The USP (United States Pharmacopoeia) defines the latest water quality standard for pharmaceutical production or manufacturing.

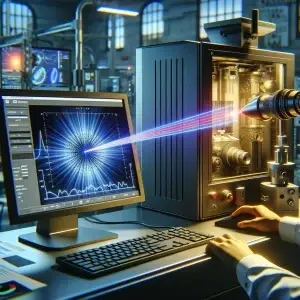

Already, many pharmaceutical companies have tried and tested different water disinfection systems. However, so far, the UV disinfection system has turned out to be the most effective method. In pharmaceutical production plants, UV light fixtures and UV chambers have been installed to prevent contamination via equipment, tools, water, and other materials.

How UVC Light Disinfection helps the Pharmaceutical Industry?

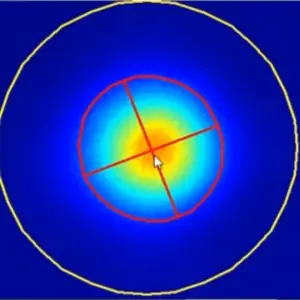

Ultraviolet-C (UVC) light, with a short wavelength of about 200 – 280 nm, acts germicidal and kills bacteria, viruses, and molds. The thymine bases present in the genetic material DNA or RNA of the microbial contaminants become reactive to UVC light when exposed and form dimers. This hinders the proliferation of the contaminants, or at times, even destroys the microorganisms.

Hence, UVC light disinfection systems are installed across various pharmaceutical industries at several points throughout the production process. Naming a few:

- Water treatment process

- Purified water storage tanks

- Wastewater in the effluent treatment plant

- Water pipelines

- Air disinfection

- Laminar Airflow Unit

- Bio-safety cabinets

- Pass boxes

- Surface and air disinfection across all entry and exit rooms

Why is UVC Light the Most Effective Disinfection Method in Pharmaceutical Production?

UVC light in Pharmaceutical production helps in,

- Microbial contaminants disinfection: UVC light destroys or inactivates the lethal microorganisms present in water used for production and the surfaces of the equipment, pipes, or tangible assets in the production plants.

- Breaking down of ozone: UVC light breaks down the ozone in the water. This ozonation of recirculating water reduces or disfavors the microorganisms (primarily bacteria) to grow further.

- Dechlorination: Even though only traces of chlorine are being added to the municipal water supply, the presence of chlorine may sometimes cause damage to the delicate membranes in the reverse osmosis equipment. The UVC light helps in the dechlorination of water after the first step of disinfection by chlorine.

- TOC reduction: The UVC light is found to be greatly effective against the low molecular weight microbial contaminants.

Benefits of UVC Disinfection in Pharmaceutical Production

Apart from effective disinfection of water in the first place, the use of UVC light disinfection systems also yields a lot of other benefits, including:

- Low-cost investment

- Non-chemical disinfection method

- No adverse effects on the product

- Easy installation and maintenance

- Less disturbance to the running production plant

- No specialized workforce needed

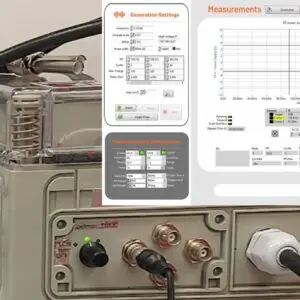

Industry’s Leading UVC Light and UV Chamber Disinfection Systems

In general, UVC disinfection system manufacturers hold years and decades of research expertise to develop tailored UV light disinfection solutions across different industries. As the market leader, Izak Scientific provides both PXL UVC light disinfection sanitizer fixtures and PXL UVC chambers specialized for pharmaceutical production. Check out now!