Modern laser beam profiling software enables real-time visualization of a laser’s intensity distribution, ensuring optimal beam quality for critical applications. Mid-wave infrared (MWIR) laser technology is increasingly vital across industries – from medical lasers like holmium (≈2.1 µm), thulium (≈2.0 µm), and erbium:YAG (≈2.94 µm) used in surgery, to industrial systems for cutting and welding, and even defense and aerospace applications such as IR countermeasures and LIDAR. Profiling these mid-IR laser beams is essential for maintaining performance and safety. MWIR lasers often operate at high peak powers in pulsed or CW modes, which means a beam profiler must capture both intense central peaks and faint edge spill-over without saturation[1]. Moreover, sensors for MWIR wavelengths require specialized cooled detectors (e.g. InSb or MCT) to achieve sufficient sensitivity and low noise[1]. Recognizing these needs, IZAK Scientific has expanded its laser beam profiler product line to cover the MWIR spectrum, providing industry professionals with the tools to thoroughly characterize beams in the ~1.5–5.7 µm range.

Key Applications for MWIR Beam Profiling

- Medical & Biomedical: Mid-IR lasers are widely used in medical procedures such as holmium:YAG and Tm fiber lasers (~2.0 µm) for surgical cutting and lithotripsy, and Er:YAG (~2.94 µm) for precise skin resurfacing, dental surgery, and ophthalmology. Beam profilers help ensure patient safety and treatment efficacy by verifying the laser’s spot size, focus quality, and energy distribution before and during use. Given the high peak powers and pulse energies of surgical lasers, a profiler with a high dynamic range is crucial to capture the full beam profile without distortion[1].

- Industrial Manufacturing: MWIR lasers (e.g. around 2–5 µm) are employed in specialized cutting, welding, and materials processing tasks – such as precision machining of plastics or glass that have particular absorption in the mid-IR. In these settings, quality assurance is paramount. A beam profiler monitors the laser’s mode structure and stability, helping maintain consistent cutting widths and weld quality. For high-power MWIR lasers used in manufacturing, the profiler’s cooling and attenuation features become important to handle intense beams safely[2].

- Aerospace & Defense: Mid-IR laser sources are central to IR countermeasure systems and LIDAR/LADAR for remote sensing. Here, profiling ensures the beam shape and divergence meet design specifications for effective targeting and detection. MWIR beam profilers with fast frame rates and trigger sync can even track rapid beam pointing or pulsing changes in military test ranges, where precise time-stamped measurements (e.g. via IRIG-B synchronization) are needed for system validation.

- Research & Development: From designing next-generation optical parametric oscillators to characterizing quantum cascade lasers, MWIR entanglement for quantum imaging or quantum technologies, R&D labs often push lasers to their limits. Continuous beam monitoring is required to verify that beam quality remains optimal under different operating conditions. MWIR beam profilers provide scientists with real-time feedback on parameters like beam width, ellipticity, and intensity profile, which is crucial for experiments in fields like quantum optics and environmental sensing. High-resolution, cooled MWIR cameras allow researchers to directly image beam profiles in the 1.5 –5 µm band – something that historically was challenging and often done with scanning slit or pyroelectric devices. The availability of modern MWIR cameras now simplifies this task, enabling two-dimensional beam profiling in a single shot with both pulsed and CW mid-IR lasers.

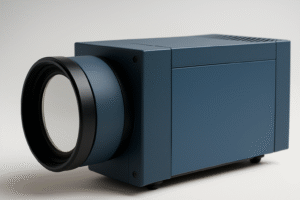

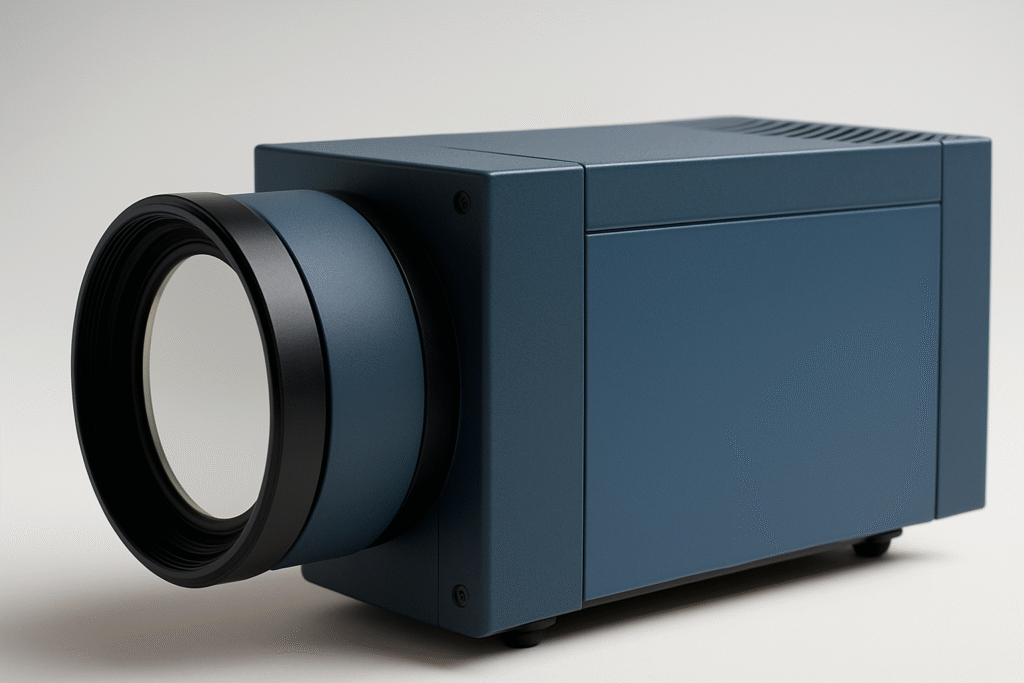

IZAK Scientific’s MWIR Beam Profiler Line-up

To meet these diverse needs, IZAK Scientific offers a range of MWIR beam profiling cameras, each optimized for different performance levels. All models employ cooled focal-plane array detectors sensitive in the mid-IR, paired with our powerful analysis software for comprehensive beam characterization. Key features like snapshot image acquisition, integrated attenuation optics, and high-speed interfaces ensure that even challenging mid-IR beams can be measured accurately. Below is an overview of the new MWIR profiler series (all accessible through our Laser Beam Profiler product page):

- MWIR-1 (3.7–4.8 µm, 0.08 MP) – A compact 320×256 resolution MWIR profiler covering the core 3.7–4.8 µm range. It offers up to 75 Hz full-frame rate, sufficient for many CW or slowly pulsed beams. With 14-bit dynamic range and a built-in cooler, MWIR-1 is a cost-effective choice for basic mid-IR profiling needs where ultra-high speed is not required. (Includes GigE interface; 5-position filter wheel and aperture wheel for adapting to various beam powers.)

- MWIR-2 (3.7–4.8 µm, 0.08 MP High-Speed) – Also 320×256 resolution, the MWIR-2 is a high-speed version of the above. It achieves an impressive 481 Hz full-frame rate (and even higher with sub-windowing), enabling the analysis of fast transients and high repetition-rate lasers. MWIR-2 features an extended 16-bit dynamic range for improved contrast, and better measurement accuracy (±1%). This model is ideal for industrial production lines or scientific experiments where real-time beam monitoring is required at video-rate or above. (Includes GigE, enhanced trigger options (4 IN / 2 OUT TTL), analog I/O for sync, and the same 5-position filter and aperture wheel.)

- MWIR-3 (1.5–5.7 µm, 0.33 MP) – A broadband MWIR beam profiler with 640×512 resolution, covering a wide spectral band from 1.5 µm to 5.7 µm. The MWIR-3’s larger 15 µm pixels and 0.33 megapixel array provide a much bigger active area (≈15.4 mm) and finer spatial detail than the 0.08 MP models – important for profiling smaller beams or seeing fine structure. Full-frame rate is 75 Hz, and dynamic range is 14-bit with ±2% accuracy. This general-purpose MWIR camera is well-suited for labs and companies working with a variety of lasers (from ~2 µm solid-state lasers to ~4–5 µm sources) where broad wavelength coverage and high resolution are more critical than extreme frame rate. (Includes GigE interface, 7-position motorized filter wheel for ND filters, and 5-position aperture wheel.)

- MWIR-4 (1.5–5.7 µm, 0.33 MP Enhanced) – The MWIR-4 builds on the 640×512 sensor platform with performance enhancements. It supports up to 151 Hz full-frame, delivering a higher frame rate for more dynamic beam analysis. The sensor readout is upgraded to 16-bit depth, boosting intra-scene dynamic range so that both low-intensity wings and bright core of the beam can be captured simultaneously. MWIR-4 also boasts ±1% measurement accuracy, making it suitable for precision tasks and calibration. With multiple trigger channels (4 IN / 2 OUT) and analog signal support, this profiler integrates seamlessly into experimental setups that demand synchronization (for instance, monitoring a pulsed laser in sync with other instruments). (Includes GigE and optional Camera Link interface for fast data, plus the 7-pos. filter and 5-pos. aperture wheels.)

- MWIR-5 (1.5–5.7 µm, 0.33 MP High-Performance) – Our flagship MWIR profiler, the MWIR-5, offers the highest speed and connectivity. It reaches up to 232 Hz at full 640×512 resolution, empowering users to capture rapid beam fluctuations or to scan across multiple beam positions quickly. Designed for demanding applications, it provides 16-bit dynamic range and ±1% accuracy like the MWIR-4, and adds expanded interface options: Gigabit Ethernet and 10 GigE for high-throughput data streaming, plus dual CameraLink outputs for integration with high-speed frame grabbers. This makes MWIR-5 ideal for high-power laser labs, defense testing ranges, or automated manufacturing cells where a large volume of profiling data must be handled in real time. (Also equipped with 7-pos. filter wheel, 5-pos. aperture wheel, and advanced synchronization including IRIG-B timestamp support for precise time logging.)

- MWIR-6 (1.5µm–5.5µm) 12.8mm Laser Beam 0.33MP – The MWIR-6 profiler delivers outstanding speed for broadband mid-wave infrared laser beam profiling (1.5–5.5 µm). Featuring a 640×512 (0.33MP) cooled detector array with 25 µm pixel pitch and a detector size of 12.8 mm, this model supports ultra-high frame rates up to 1,004 Hz at full-frame, extending to 30,330 Hz in sub-frame mode. With 14-bit dynamic range and ±1% accuracy, it’s suited for rapid beam diagnostics and dynamic profiling tasks. Equipped with a 7-position filter wheel, 5-position aperture wheel, and 10 GigE interface, it provides flexibility and high-speed data transfer.

- MWIR-7 (1.5µm–5.5µm) 10.2mm Laser Beam 1.3MP – The MWIR-7 features a high-resolution, 1.3MP (1280×1024) cooled detector with 10 µm pixel pitch for detailed beam profiling in the 1.5–5.5 µm range. It captures up to 180 Hz full-frame and up to 2,601 Hz in sub-frame modes, ideal for precise beam analysis and mode inspection. Enhanced synchronization capabilities, including 4 IN / 2 OUT TTL triggers, analog signals, and IRIG-B, facilitate integration into advanced testing environments. Includes versatile connectivity options: GigE, 10 GigE, CAMLink, and HDMI, plus motorized optical attenuation (7-position filter and 5-position aperture wheels).

- MWIR-8 (1.5µm–5.5µm) 10.2mm Laser Beam 0.33MP – Designed for versatility and speed, the MWIR-8 incorporates a 640×512 (0.33MP) detector with 20 µm pixel pitch, offering high-speed profiling at frame rates up to 622 Hz (full-frame) and up to 3,343 Hz (sub-frame). With 16-bit dynamic range and ±1% accuracy, it excels at detailed imaging and beam diagnostics. Connectivity includes 10 GigE, CAMLink, HDMI interfaces, and advanced synchronization options. Equipped with motorized 7-position optical filters and 5-position aperture wheels for adaptable attenuation.

- MWIR-9 (1.5µm–5.5µm) 10.2mm Laser Beam 1.3MP – The MWIR-9 offers outstanding resolution and frame rate flexibility, featuring a 1.3MP (1280×1024) cooled detector with a 10 µm pixel pitch. Covering a broad spectral range (1.5–5.5 µm), it achieves up to 180 Hz full-frame and ultra-high-speed modes up to 3,343 Hz. Its 16-bit dynamic range and ±1% accuracy ensure superior beam profiling precision. With extensive interface options (GigE, 10 GigE, CAMLink, HDMI), advanced triggers, and integrated attenuation optics, it’s ideal for complex testing setups.

- MWIR-10 (3.5µm–4.8µm) 8.6mm Laser Beam 0.92MP – The MWIR-10 is tailored specifically for detailed profiling within the narrower MWIR spectral range (3.5–4.8 µm). It features a high-resolution 1280×720 (0.92MP) cooled detector array with 12 µm pixel pitch, offering frame rates up to 120 Hz (full-frame) and exceptional high-speed imaging at 16,053 Hz in sub-frame mode. With 14-bit dynamic range, ±1% accuracy, and multiple interface options (GigE, 10 GigE, dual CAMLink, HDMI), this profiler is perfect for applications demanding both precision and speed.

- MWIR-11 (3.6µm–4.9µm) 15.4mm Laser Beam 2.95MP – The MWIR-11 profiler sets a new benchmark with its exceptionally high-resolution 2.95MP (1920×1536) cooled detector and a broad detector area of 15.4 mm. Operating in the 3.6–4.9 µm wavelength range, it offers up to 113 Hz at full-frame with high-speed modes up to 2,493 Hz. With a dynamic range of 14-bit and accuracy of ±1%, it is ideal for advanced research and industrial applications demanding unparalleled imaging detail. Interfaces include 10 GigE and HDMI, enhanced by flexible trigger and analog synchronization options.

All MWIR models come with IZAK’s Beam Profiler software, which offers a rich suite of analysis functions. Users can measure all the critical beam parameters – from beam width and diameter to intensity profile shape, ellipticity, beam centroid, divergence, and more[1]. The software provides 2D/3D visualizations of the beam and can track changes over time, enabling real-time adjustments to your laser system. Whether you need to fine-tune a laser’s focus in a lab or monitor beam quality on a production line, these profilers deliver the data you need. And thanks to features like motorized filter wheels and apertures, you can easily adapt to different power levels and beam sizes without manual intervention, protecting the sensor while maintaining measurement accuracy.

Selecting the Right MWIR Beam Profiler

Choosing the most suitable MWIR profiler from our lineup depends on your specific laser parameters and application goals. Here are some guidelines to help identify the best fit:

- Wavelength Coverage: Consider the laser’s wavelength. If you only work with lasers in the ~3.7–4.8 µm range (for example, certain carbon monoxide or quantum cascade lasers), the narrower-band models MWIR-1 or MWIR-2 will cover those needs cost-effectively. However, if your applications include any shorter wavelengths around 1.5–3 µm (e.g. Ho:YAG at 2.1 µm, Er:YAG at 2.9 µm) or extend beyond 5 µm, you’ll need one of the broadband models (MWIR-3, 4, or 5) that span 1.5–5.7 µm.

- Beam Size & Resolution: The size of the beam spot and the level of detail required should inform your choice of resolution. Higher-resolution cameras (640×512 in MWIR-3/4/5) can resolve finer features and smaller beam diameters than the 320×256 sensors (MWIR-1/2). Remember that IR camera pixels are relatively large (15–30 µm), which means a very small beam may only cover a few pixels if resolution is low. If you anticipate measuring beams on the order of a few hundred microns, the VGA resolution models will provide significantly better spatial sampling and accuracy. On the other hand, for very large beams or less detail-critical measurements, the QVGA resolution of MWIR-1/2 may suffice.

- Temporal Dynamics: Think about how fast your laser’s output changes. For slowly varying or CW beams, a 75 Hz frame rate (MWIR-1/MWIR-3) is usually adequate. But for high repetition-rate pulsed lasers, modulated beams, or active feedback control, a high-speed profiler is invaluable. MWIR-2 offers up to 481 Hz full-frame – ideal for catching rapid pulse-to-pulse fluctuations or beam jitter in real time. MWIR-5, at 232 Hz, is also suited for fast monitoring, especially when combined with its large frame for capturing the whole beam. If ultra-high-speed or specialized high-frame sub-window modes are needed (tens of kHz with reduced resolution), MWIR-2 has the edge with its exceptional sub-frame rates. In summary, choose MWIR-2 or MWIR-5 when beam dynamics are a primary concern, so you never miss a transient event.

See demo – Basic Operation of IZAK’s Beam Profiler Application

- Power & Dynamic Range: For lasers with very high peak power or very contrasty profiles (bright core and weak tails), prioritizing dynamic range and built-in attenuation is key. The 16-bit sensors in MWIR-2, MWIR-4, MWIR-5 can distinguish subtle intensity variations across a wide range in a single shot, whereas 14-bit models have slightly lower dynamic range. Additionally, MWIR-3/4/5 include a 7-position neutral density filter wheel (versus 5-pos on MWIR-1/2) – this means more flexibility to dial in the right attenuation for very powerful beams, preventing detector saturation while preserving beam shape integrity. If you plan to profile a laser that operates near the edge of the profiler’s damage threshold or has a highly variable power, opting for the higher-dynamic-range model will ensure accurate, linear measurements of both low and high intensities in the beam[2].

- Integration & Advanced Features: Consider the environment in which the profiler will be used. For standalone lab use, any of the models can connect via standard GigE to a PC for data acquisition. But in more complex setups, certain features become advantageous. For example, MWIR-4 and MWIR-5 provide multiple trigger I/O lines – if you need to synchronize the camera with other equipment (such as pulsing the laser or gating an experiment when the camera is ready), these models offer the necessary hardware hookups. MWIR-5 further adds 10 GigE and dual CameraLink outputs; if you need to stream a firehose of data (e.g. in high-volume production testing or when recording long sequences of high-speed frames), the extra bandwidth ensures you won’t be bottlenecked. MWIR-5’s support for IRIG-B timecode is also valuable in defense or aerospace testing, where coordinating timestamped measurements from multiple instruments is required. In short, for cutting-edge R&D or integrated systems, the top-tier MWIR-5 provides maximum connectivity and upgradability, whereas MWIR-4 covers many of the same advanced sync features at a slightly lower cost if ultra-high data throughput isn’t needed. For simpler setups, MWIR-1/2/3 will get the job done without the additional frills.

By evaluating your use case against these criteria – wavelengths involved, beam size, how fast things change, power levels, and system integration needs – you can confidently select an MWIR beam profiler that best aligns with your requirements. Of course, all our MWIR profilers share the IZAK Scientific pedigree of quality and come calibrated for accurate measurements. If you’re still unsure which model fits your application, our team is happy to help analyze your laser specs and recommend an optimal solution.

Customization & Integration Capabilities

Beyond our standard models, IZAK Scientific can customize the beam profiler software to meet customer-specific needs, including:

· Tailored measurement workflows

· Custom data output formats for integration into your existing QA systems

· Automated pass/fail algorithms for production lines

We also offer hardware integration:

· Optical attenuation stages (ND filters, beam splitters)

· Additional measurement modules, such as:

o Beam power measurement

o Energy-per-pulse capture for pulsed lasers

o Fast temporal pulse shape measurements using a photodiode, integrated with our TriBeam Precision platform

· Inspection & test system integration, adding:

o Temperature sensors

o Motion control stages

o Data logging and reporting tools

o Specialized image processing tailored to your application

Whether you require a standalone laboratory profiler or a fully integrated, automated inspection system, IZAK Scientific can deliver a turnkey solution built around our MWIR beam profiler technology.

Conclusion

The addition of these advanced MWIR beam profilers to our product lineup means that no matter the laser wavelength from UV through LWIR, IZAK Scientific has you covered[3]. The mid-IR range in particular opens new frontiers – enabling precise profiling of lasers that were once difficult to characterize. By choosing the right MWIR profiler, companies in healthcare, manufacturing, defense, and research can now reliably measure and tune their mid-infrared lasers, ensuring better performance and outcomes. All the models discussed are available on our website (as variants under the Laser Beam Profiler product page) along with detailed specifications for side-by-side comparison. We invite you to explore our MWIR offerings and reach out to IZAK Scientific for any guidance in beam profiler selection or to discuss your unique laser profiling challenges. With the proper tools in hand, you can fully unlock the potential of your MWIR lasers, achieving the precision and control that your cutting-edge applications demand. [1]

Visit our Laser Beam Profiler page to compare models and specifications, or contact us to discuss your specific application. Together, we’ll ensure your MWIR laser beams are measured, monitored, and optimized to the highest standard.

See demo – Test and Report Feature:

See demo – Fractional Laser Beam Profiler Feature:

[1] Laser beam profiler selection guide – izakscientific

https://izakscientific.com/laser-beam-profiler-selection-guide/

[2] TriBeam Precision

https://izakscientific.com/product/tribeam-precision/

[3] Illuminating Precision: The Integral Role of Laser Beam Profiling Across Industries – izakscientific

Tzachi Sabati

CEO, IZAK Scientific

Physicist specializing in photonics and quantum technologies, with deep expertise in quantum sensors and advanced optical systems. Leads the Advanced Quantum Lab course at the Technion, bridging academic excellence with industry innovation. At IZAK Scientific, provides cutting-edge photonics-based solutions, developing customized inspection and sensing systems for R&D and production. Passionate about advancing quantum sensing applications and integrating novel technologies to meet industry needs.