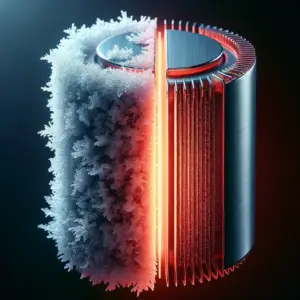

Thermoelectric coolers (TECs), also known as Peltier devices, have become a pivotal component in modern cooling technology. Their unique ability to transfer heat from one side of the device to the other without moving parts or fluids makes them ideal for various applications.

How Do Thermoelectric Coolers Work?

TECs operate on the Peltier effect, named after French physicist Jean Charles Athanase Peltier. This effect occurs when an electric current passes through two different conductors or semiconductors, causing heat transfer from one side of the device to the other. This creates a hot and a cold side, allowing for cooling or heating, depending on the direction of the current.

The core components of a TEC are the Peltier modules, which consist of several pairs of n-type and p-type semiconductor materials connected in series. As current flows through these pairs, heat is absorbed at the junctions, creating a temperature difference.

Applications of TECs in Devices

The applications of TECs are vast and varied, including:

1. Laser technology for: maintaining precise temperature control of laser diodes, ensuring stable performance and efficiency. They are key in applications ranging from medical equipment to optical communication, enhancing laser reliability and accuracy. This enhances the performance, reliability, and lifespan of laser systems across various industries.

2. Medical Equipment: For precise temperature control in laboratory equipment like PCR machines.

3. Skin Treatments and Aesthetic Devices: In dermatology, TECs are used in skin cooling devices that protect skin during laser treatments or other thermal-based procedures

4. Telecommunications: In outdoor enclosures to regulate the temperature of sensitive electronic components.

5. Imaging Equipment: Certain imaging technologies, like infrared cameras used in diagnostics, and radiometry may use TECs to maintain the temperature of sensitive components.

6. Automotive Industry: For cooling or heating car seats.

7. Patient Comfort Devices: Devices such as therapeutic cooling/warming blankets, which are used to regulate patient body temperature in clinical settings, often use TECs

8. Consumer Electronics: In portable coolers, wine coolers, and air conditioners.

In these applications, the ability of TECs to provide precise, rapid, and reliable temperature control without moving parts is invaluable.

TEC Manufacturing and Variability

Manufacturing TECs involves a meticulous process to ensure the precise alignment and connection of the semiconductor pairs. However, there are often subtle differences between TEC units within a production batch and between different batches. These variances can arise from slight differences in material properties, manufacturing processes, or handling. Such differences, though minute, can significantly impact the performance and reliability of the TECs.

Testing and Quality Assurance

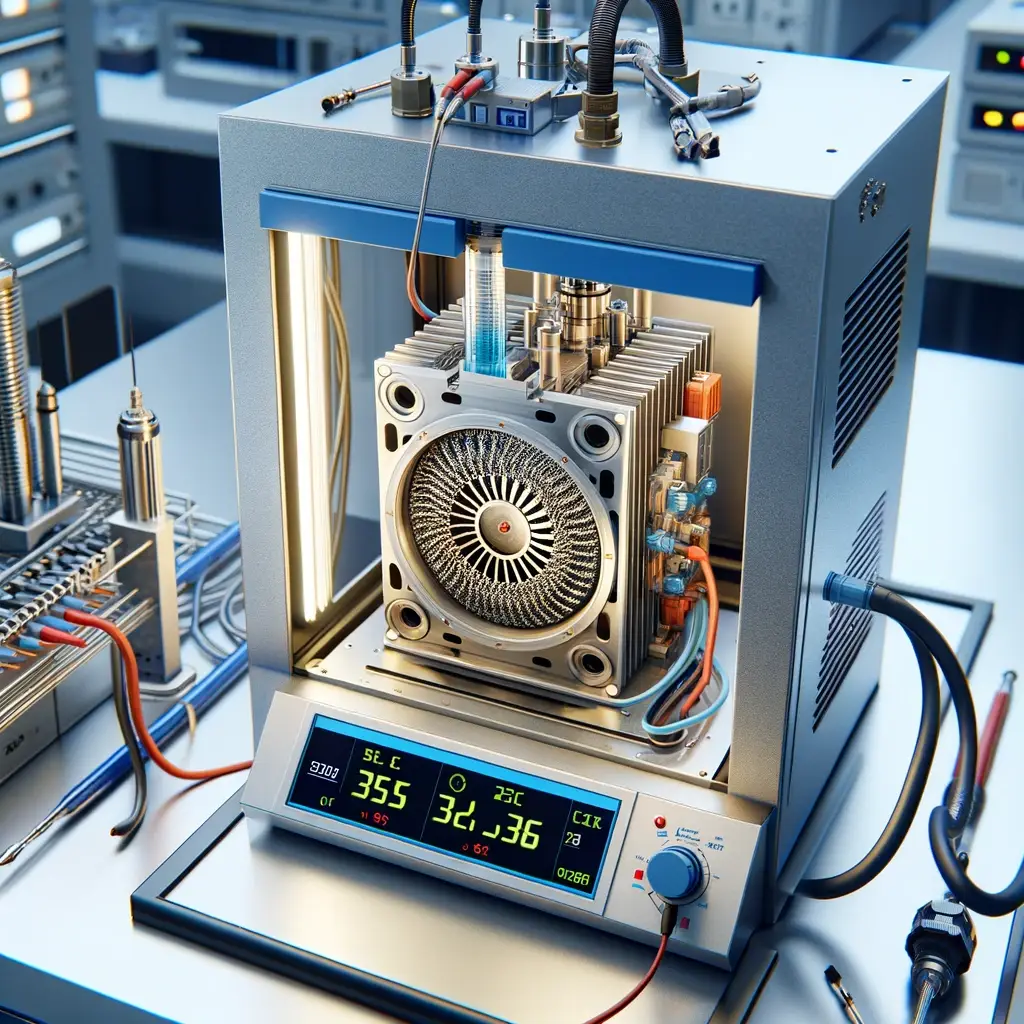

But, like any component, ensuring their quality and consistency is crucial, particularly for companies incorporating TECs into their products. This is where the importance of testing, specifically using tools like the IZAK Scientific TEC Tester, becomes evident. Companies incorporating TECs into their products must conduct rigorous testing to ensure quality and consistency. The recommended test list for quality assurance before installation includes:

1. Performance Test: Assessing the maximum temperature differential, heat pumping capacity, and power consumption.

2. Electrical Test: measurement of TEC current, checking for electrical resistivity and insulation resistance.

3. Physical Inspection: Ensuring there is no physical damages or defects.

4. Environmental Test: Testing the TEC’s performance under various environmental conditions like humidity and temperature.

5. Durability Test: Evaluating the TEC’s lifespan under cyclic temperature and load conditions.

Importance of Comprehensive Testing

Implementing a thorough testing regime using tools like the IZAK Scientific TEC Tester is crucial for several reasons:

· Ensuring Reliability: Identifies potential failures or underperforming units before installation.

· Maintaining Consistency: Assures uniformity in performance across batches.

· Product Development: Provides valuable data for improving TEC design and efficiency.

· Compliance with Standards: Ensures products meet industry-specific regulations and standards.

In conclusion, as the use of TECs grows across various industries, the importance of ensuring their quality cannot be overstated. The IZAK Scientific TEC Tester represents a vital tool in this process, providing an efficient and reliable means for companies to test and certify the performance and durability of their thermoelectric coolers. By investing in such testing processes, companies can enhance the reliability of their products, maintain high customer satisfaction, and stay competitive in a market where precision cooling is increasingly essential.

The IZAK Scientific TEC Tester

The IZAK Scientific TEC Tester is an advanced solution designed for comprehensive testing of thermoelectric coolers. This tester, combined with specialized software, provides a thorough analysis of TEC performance and reliability. Key features include:

· Automated Testing: Facilitates large-scale testing with minimal manual intervention.

· Precision Measurement: Accurately measures key performance parameters.

· Software Integration: Offers software tools for data analysis and reporting.

· Customization: Adaptable to different TEC types and testing protocols.

· Documentation: Generates detailed reports for quality control documentation, adhering to industry standards.

Tzachi Sabati

CEO, IZAK Scientific

Physicist specializing in photonics and quantum technologies, with deep expertise in quantum sensors and advanced optical systems. Leads the Advanced Quantum Lab course at the Technion, bridging academic excellence with industry innovation. At IZAK Scientific, provides cutting-edge photonics-based solutions, developing customized inspection and sensing systems for R&D and production. Passionate about advancing quantum sensing applications and integrating novel technologies to meet industry needs.