There are many UV disinfectants on the market nowadays. With a few clicks of a mouse, anyone can buy one, hoping that will kill 99% of bacteria and viruses. However, if you read this article you may think twice before ordering one. UVC technology had been around for almost 100 years and had been consistently found effective ….when used by researchers. UVC light works extremely well as a UV disinfectant- when used properly.

UV Light Dose

A key component of successful UV-C disinfection is the UVC light dose. The dose is the amount of UVC light that a bacterium or virus will absorb. Different microbes will require different doses of UVC light to be killed or inactivated.

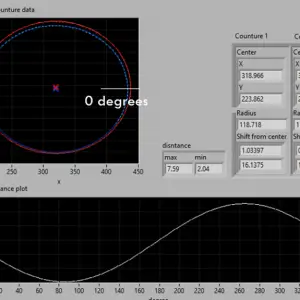

The UVC dose is expressed in mJ/cm2 and is calculated using the formula for water and air disinfection: UV dose (μW·s/cm2) = UV intensity (μW/cm2) × exposure time (seconds)

The dose can be raised by 1) increasing the strength of the UVC source, 2) increasing the time/exposure to the UVC light or 3) by decreasing the distance between UV light source and the object that has to be disinfected.

The UV Wavelength And Other Measurements

In addition to the UV dose, researchers also use other measurements such as dose rate, exposure dose, fluence rate, and radiance. Talking about radiance- this measure can be used to evaluate both the efficacy and safety of a device. As an example, a xenon pulsed lamp has a very high radiance and the energy can be focused to produce a very high irradiance on specific tissue. On the other hand, the radiance of the fluorescent lamp tube is much lower. As a result, its energy can not be focused to a high concentration on the target tissue.

Surface, Water, and Air Disinfection

Another key factor to consider is the surface that requires UV disinfection. For example, contaminated cardboard will require different exposure to UVC light compared with a medical mask or a food package. There is also the humidity factor that has to be considered when buying a UV disinfectant.

For water disinfection, the U.S. The Environmental Protection Agency (EPA) publishes specific UV dosage guidelines because the UV dose cannot be measured directly. Instead, it is estimated taking into consideration: flow rate (or contact time), transmittance, turbidity (cloudiness), and the lamp age (or other factors that can reduce the UV intensity).

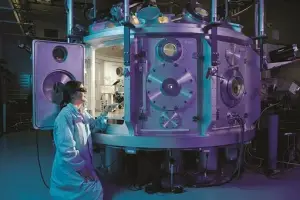

The Type Of UVC Light

There are three major types of UV disinfectants (UVC) in today’s market: LED-UVC, low-pressure mercury lamp, and the more advanced technology pulsed xenon light (PXL). This article explains the differences between them. Research suggests that PXL has a broader antimicrobial spectrum, is extremely reliable, has low energy costs, and is also eco friendly.

As you may notice, there are a lot of factors to consider, and many measurements to be done. That’s why is critical to work with a team of specialists to get the right recommendations on how to use UVC light and the best UVC device that suits your needs. Whether you need small or larger surfaces for disinfection, IZAK Scientific has a solution for you. Full training and safety instructions available. Email us today!

- https://www.fda.gov/media/101349/download

- https://www.cdc.gov/infectioncontrol/guidelines/disinfection/

- “Ultraviolet Light in Food Technology: Principles and Applications” By Tatiana Koutchma

Tzachi Sabati