The Essentials of Laser Beam Profiling: Enhancing Laser Quality Assurance

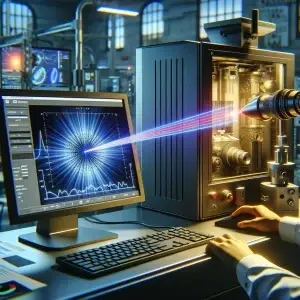

In the intricate world of laser technology, achieving unparalleled precision and efficiency is of utmost importance. This is especially true across various applications where the fine-tuning of laser performance can make a significant difference. Enter the laser beam profiler—a critical tool that plays a pivotal role in measuring and optimizing the characteristics of laser beams, ensuring they meet the highest standards of quality. This comprehensive exploration will delve into the essentials of laser beam profiling, underscoring its importance in laser quality assurance and its broad range of applications.

Understanding Laser Beam Profiling

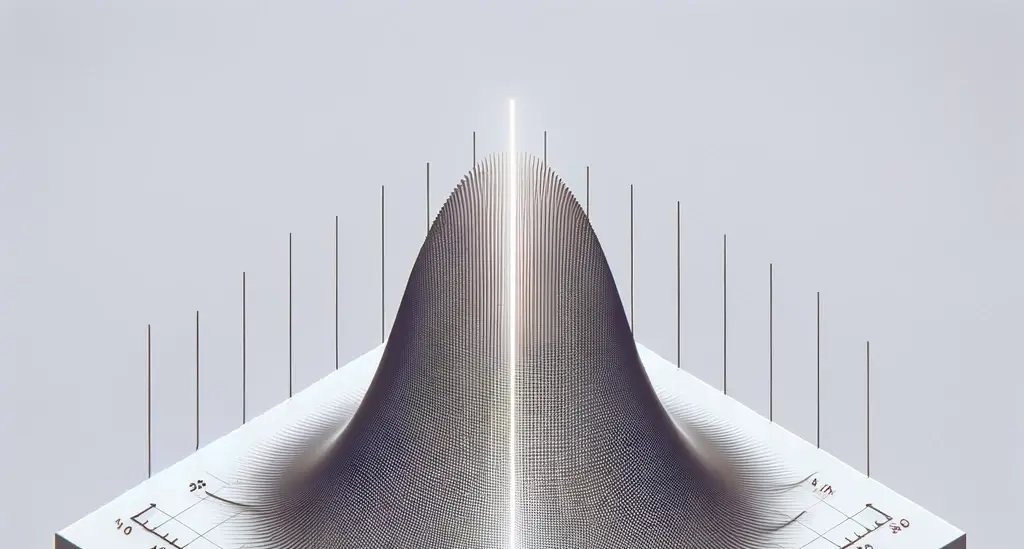

Laser beam profiling is a sophisticated technique used to analyze the shape, intensity distribution, and spatial properties of a laser beam. Unlike the limited perception capabilities of the human eye, a laser beam profiler provides an intricate map detailing these crucial characteristics. Such detailed insights are indispensable for gauging how a laser will interact with different materials, ensuring the laser performs consistently and produces predictable results.

The Importance of Profiling in Laser Quality Assurance

The quality of a laser beam has a direct impact on the effectiveness of its application. For instance, in the precision-required field of laser surgery, the accuracy of the beam’s focus is paramount to perform surgeries with minimal collateral damage. In the manufacturing sector, the uniformity and intensity of the laser beam influence the quality of cutting, welding, and material processing tasks. By employing a laser beam profiler, operators can fine-tune their laser systems, ensuring optimal operation and superior outcomes.

Key Measurements Facilitated by Laser Beam Profilers

A laser beam profiler is engineered to evaluate several vital characteristics of laser beams, including:

- Beam Width/Diameter: This measurement pertains to the laser beam’s width, which is crucial for precise focusing.

- Beam Shape: The profiler identifies whether a beam is circular, elliptical, or possesses any irregularities, affecting the laser’s interaction with surfaces.

- Intensity Distribution: This aspect quantifies the distribution of power across the beam, which is vital for applications requiring uniform intensity.

Research and Development

The development of new laser technologies and the study of beam propagation heavily rely on laser beam profiling for accurate characterization.

Medical Applications

In surgeries or dermatological treatments, laser beam profilers calibrate lasers for precise operations, at production quality assurance ensuring minimal deviation from beam specifications..

Manufacturing

For processes such as laser cutting and welding, maintaining consistent beam quality is essential for producing high-quality outcomes. Laser beam profilers enable the necessary adjustments for peak laser performance.

Quality Assurance

Regular use of laser beam profilers helps maintain lasers within operational specifications, upholding the quality and safety of laser applications.

Technological Foundations of Laser Beam Profiling

Laser beam profiling employs various technologies, each suited to specific laser types and applications:

· CCD/CMOS Cameras: Utilized for visible to near-infrared lasers, these cameras capture detailed beam cross-section images.

· Scanning Slit Profilers: By scanning a narrow slit across the beam, these profilers construct a profile detailing the beam’s intensity distribution and width.

· Pyroelectric Detectors: Ideal for high-power or pulsed lasers, these detectors measure the energy distribution within the beam.

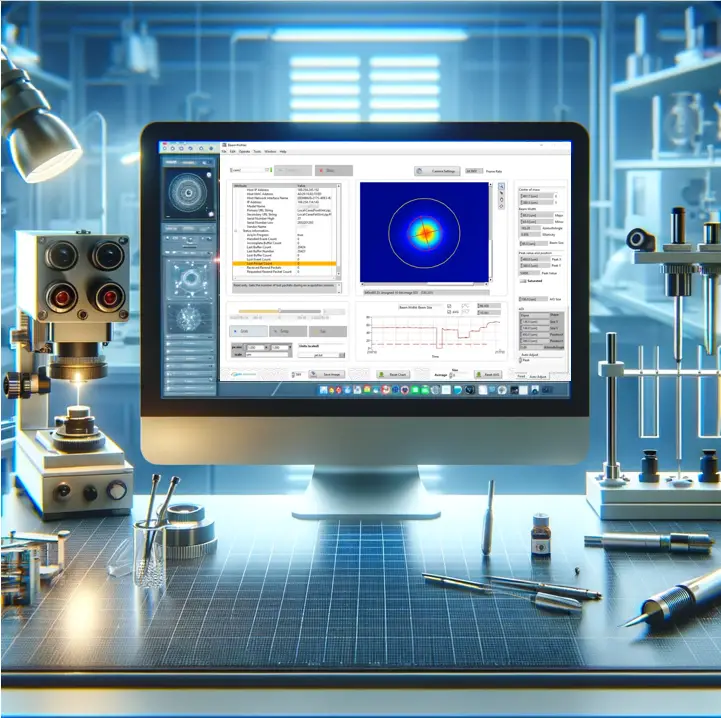

IZAK Scientific’s Customizable Laser Beam Profiler for Enhanced Quality Assurance

The ability to tailor the system to specific laser characteristics and operational requirements ensures that users can achieve optimal performance and quality assurance.

The main features exhibits real-time laser beam analysis calculates essential laser beam properties within the Region of Interest (ROI). Measurements include:

· Beam center (X, Y positions)

· Beam width (major and minor ellipse axes)

· Azimuth angle

· Ellipticity

· Beam size

· ROI size

By incorporating IZAK Scientific’s laser beam profiler into their quality assurance protocols, these features are delivered as tester software application as well with success (pass/fail) criteria and report for documentation. In addition The application can be customized as organizations can significantly enhance the precision, efficiency, and reliability of their laser applications. This level of customization and system integration offered by IZAK Scientific exemplifies the advancements in laser beam profiling technology, ensuring that users are equipped with the tools necessary to meet the stringent demands of modern laser applications.

Conclusions

Laser beam profiling is an indispensable element of laser quality assurance. It provides the detailed insights necessary for the fine-tuning of lasers across a wide spectrum of applications, from medical procedures to precision manufacturing. As the field of laser technology continues to expand, the role of the laser beam profiler will become increasingly crucial, ensuring the continued advancement and application of laser technologies in various industries. Mastery and implementation of laser beam profiling are key to leveraging the full capabilities of laser technologies, pushing the envelope of innovation in medical treatments, manufacturing precision, and beyond.