Part of the process of fast prototyping involves understanding the best setup. With any kind of programmable firmware, FPGA for an electro-optics setup can be very useful. For feedback loop control, design parameters that are simple to reconfigure and even basic hardware testing, FPGA is a valuable tool in your toolbox.

Using a field-programmable gate array or FPGA microchip involves using its ability to easily be reprogrammed. Many types of processors just run software applications, but FPGA chips rewire to implement your intended function. This can work through numerous types of hardware platforms, embed in many types of systems and can control everything from the angle of scan or power source to the settings of a detector, as well as other functions.

While software may work in some applications, the physical connections in an FPGA are more effective. This also permits greater amounts of functionality for the memory used, which is both energy efficient and more compact than software based applications are. A primary benefit is the use of upgrades in the software, which can fix bugs and provide additional features, which even allows the engagement of researching and developing numerous test case scenarios. In both industry and the lab, this is a vital function of FPGAs.

The Laboratory Virtual Instrument Engineering Workbench or LabVIEW is a language used for visual programming that can provide virtually every function that a properly equipped engineering lab can. This can be integrated with both virtual instruments and physical hardware, and can acquire data easily. This can also graph and analyze the data, as well as display it and offer feedback in real time. The combination of these functions allows for rapid alterations to prototypes through measuring and analyzing the data, and this allows for optical test projects.

The control you can use for detectors, cameras, lasers, lamps, modulators and other devices can work well through FPGA chips. Many photonic systems use them, as do the switches in lamps and lasers. This is a simple application, and more complicated ones include controlling the parameters of wavelength and output power. With feedback and control of this magnitude, many things are possible.

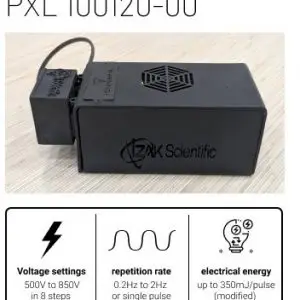

IZAK Scientific can integrate and effectively automate the control and testing process into electro optical systems. One recent time the company did this was to set up an automated test for a client using LabVIEW and experience with optics hardware. IZAK Scientific was able to provide a large amount of captured data and the changes that took place. This came about through feedback acquired in real time. This also made use of modular programming.

As a successful proof of concept, this brought together National Instruments FPGA CompactRIO. As well, the company used temperature and light sensors and a light source. A useful factor was the light source itself. LabVIEW can run a routine that controls flash lamps and photodiodes, and the monitored power can be adjusted when necessary. CompactRIO or Reconfigurable Input/Output can use its swappable I/O modules to be more flexible, as well as providing controls for applications including processing and conditioning signals.

This can also read multiple forms of input, adjust lamp or laser sources, change mirror and lens positions, and reform many other types of variables useful to the testing process. The reprogrammability, reuse, flexibility and rapid time to market also make FPGA ideal for testing. As well, a closed loop control and determinism also make FPGA desirable.

Purpose:

Software is used in such an application to detect temperature and light level within a given area, then this is used to illuminate a closed loop control area. In cases of higher illumination or temperature, the intensity decreased accordingly. The inverse was also true. This is used to test a hypothetical setup, purchase components, perform a test optically and then build the finished product with included instructions on its use to the client. With the CompactRIO module and LabVIEW, the project was successful.

Procedure:

- The company chose primary components for source, sensing and detection.

- The company setup hardware into a functional system.

- The company determined the relevant test parameters and feedback information.

- The company wrote routines for LabView to rapidly debug and change system parameters to expand functions.

- CompactRIO and LabVIEW allowed the controls and alterations as necessary.

- The company analyzed the graphs and data.

- The company adjusted the data with LabVIEW to accommodate the data.

- The company evaluated the results and made according suggestions.

This optical system analysis shows that IZAK Scientific is excellent at identifying and working within client needs. These parameters are individual, and each client should have a conversation to identify how we can help them.

Tzachi Sabati

CEO, IZAK Scientific

Physicist specializing in photonics and quantum technologies, with deep expertise in quantum sensors and advanced optical systems. Leads the Advanced Quantum Lab course at the Technion, bridging academic excellence with industry innovation. At IZAK Scientific, provides cutting-edge photonics-based solutions, developing customized inspection and sensing systems for R&D and production. Passionate about advancing quantum sensing applications and integrating novel technologies to meet industry needs.