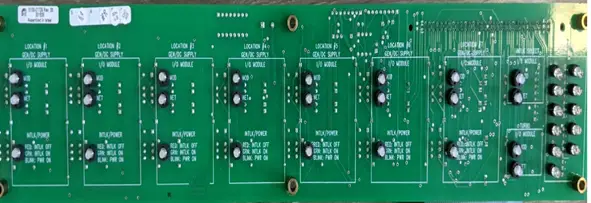

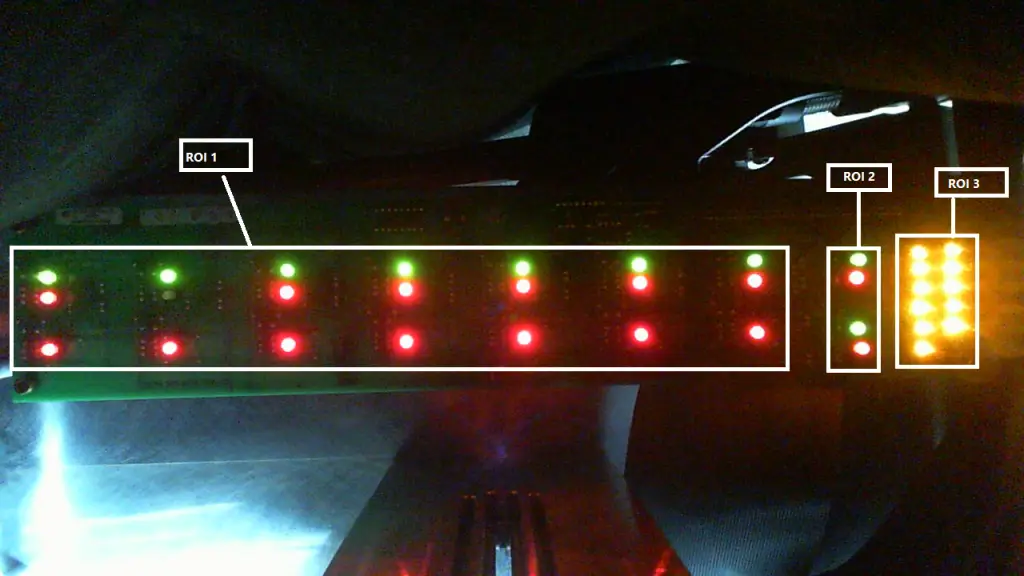

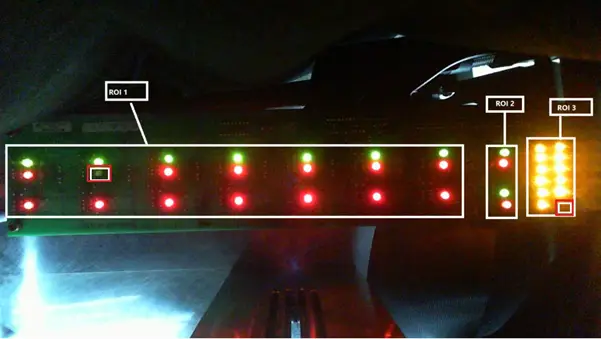

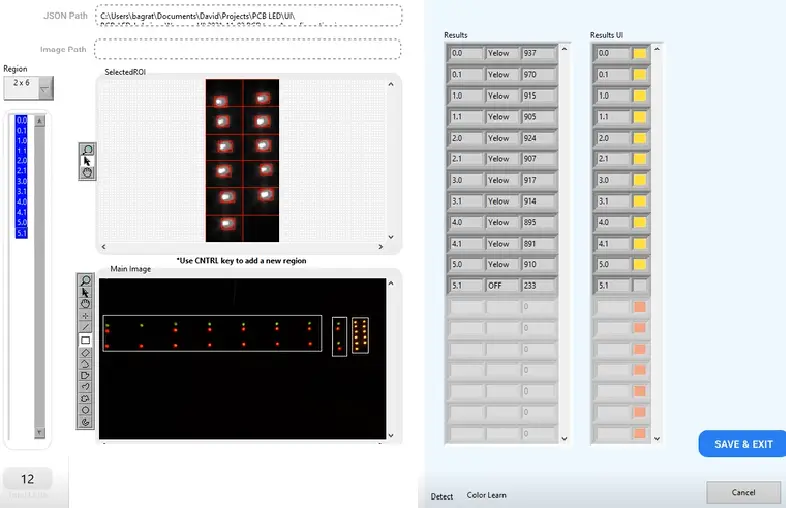

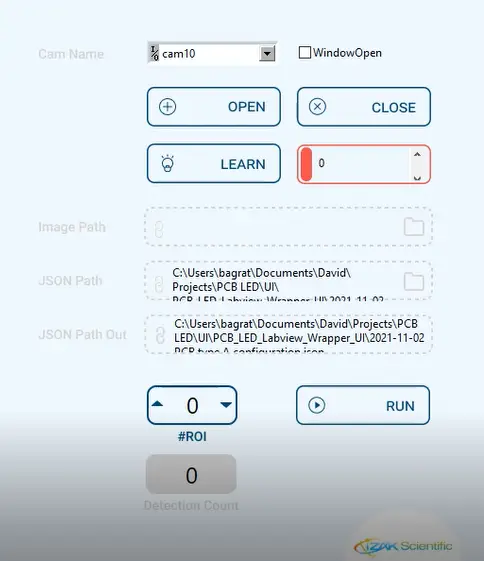

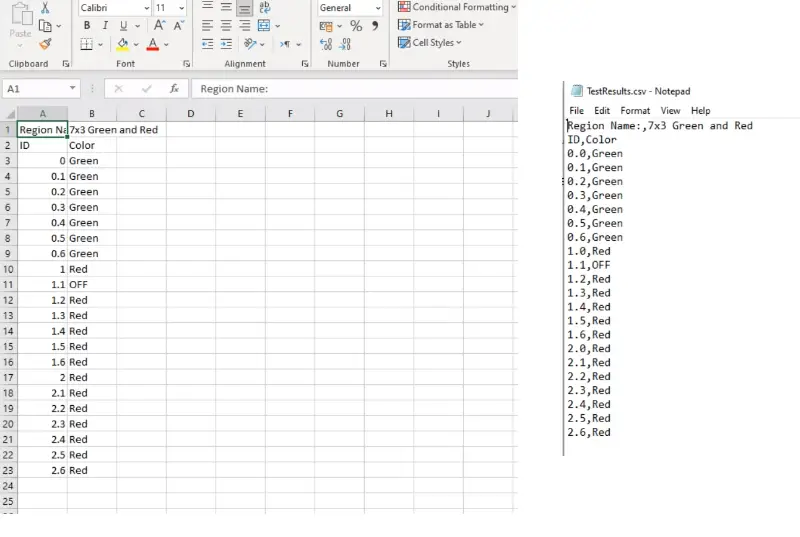

We purchased LED Color and position tester from IZAK Scientific after having successful projects before and due to their great skills and fast delivery. We needed a solution to test different PCBs, with each PCB having a few LED configurations. IZAK Scientific, led by Tzachi, delivered us an API (dll file) for the LED Tester, along with an example in the LabWindows CVI environment. We integrated IZAK’s LED tester in our tester software. In addition, IZAK also delivered a tester box with an imager and optics, along with relays as a system.

IZAK LED Tester API is a smart and simple, easy-to-learn machine-learning algorithm that learns new PCB in a few minutes. The system allows us to test our PCB quickly and easily in free space configuration. As we integrated the system, we got a full service customized to our specific needs, along with the support from IZAK’s great team.

This was one of few projects we made with Izak Scientific, and the team proved to be professional, with on-time delivery.

Tzachi Sabati