Product packaging is considered one of the major doors that open up to microbial contaminations. Industries that produce microbiologically-demanding products, such as cosmetics, foods, and pharmaceuticals, are bound to prioritize quality packaging. Perhaps, quality packaging without microbial contamination will be their everlasting goal.

Different disinfection methods are deployed across industries, including the thermal and non-thermal approach, chemical surface cleaning, UV light, gamma, and electron beam radiation. With respect to the food industry, UV light disinfection methods serve as the best and go-to option among the other disinfection methods.

Factors Influencing Industrial Food Packaging

Microbial strains: There is a huge probability that food products could be affected by bacteria, viruses, fungi, mold, yeast, and similar microbes present in the packaging surfaces.

Machines and Equipment: For food packaging, filling and sealing machines are of great use. The surface of this equipment might house millions of harmful microbes and contaminants.

Shape or geometry of the packaging: Food packaging involves the use of bottles, caps, containers, cups, knobs, pots, foils, bags, glass necks, paper plates, jars, and a lot more items.

HVAC system: An HVAC system is essential for ecological balance in the food packaging rooms. The presence of air conditioning allows microbes to spread via air easily.

Type of food product: The consistency of the food products, such as liquid, fluid, solid, powder, watery, semi-solid, and dry, plays a vital role in deciding the disinfection method of the packaging.

The Germicidal UVC Light

UVC light (265 nm) has shown high potency against the microbial contaminants. At this wavelength, the UVC light acts germicidal and kills the microorganisms. Upon reaching the microbes, the UVC light penetrates their cells, causes damage to their genetic material (DNA/ RNA), and prohibits further proliferation stages. This way, the microbes are either destroyed or prevented from proliferating.

When packaging materials like cups, bottles, and caps undergo UVC disinfection, it ensures the inactivation of microbiological contaminants already present and prevents further contaminants from entering the surface of the disinfected materials.

Once the packaging materials are UVC disinfected, the food products can then be aseptically filled in the sterilized containers and sealed, thus preventing the entry of microbial contaminants even at the stage of product filling.

Recommended UVC Disinfection in Food Packaging

Industry experts have suggested a list of food products that can stand with UVC-disinfected food packages:

- Containers for organic food products

- The conveyor belt that passes on fruits, vegetables, fish, and meat

- Packaging cans for fresh milk

- Sachets involved in the cold filling of fluids, such as sauce, ketchup, mayonnaise, dips, and condiments

- Caps of bottles and jars

- Powder bags and films

Advantages of UVC Light Disinfection in Food Packaging

Industrial-grade hygienic packaging

- Supports both dry and cold disinfection

- 100% disinfection

- Environmentally friendly

- Human safe

- Easy retrofitting

- No chemicals involved

- Durable with low maintenance

- Energy and cost-efficient

- Requires no specific skills

Provide Hygienic and Contaminant-Free Food Products

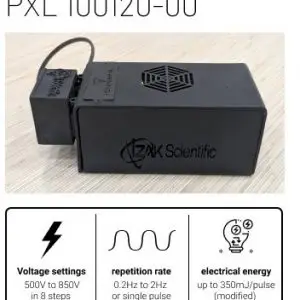

Explore the power of pulsed-xenon-based UVC light sanitizer and UVC chamber that helps you with easy, quick, and quality packaging disinfection.

Enough of struggling with low-cost and ineffective packaging disinfection methods! Be the first in the market to provide contaminant-free food products to your customers!

Tzachi Sabati

CEO, IZAK Scientific

Physicist specializing in photonics and quantum technologies, with deep expertise in quantum sensors and advanced optical systems. Leads the Advanced Quantum Lab course at the Technion, bridging academic excellence with industry innovation. At IZAK Scientific, provides cutting-edge photonics-based solutions, developing customized inspection and sensing systems for R&D and production. Passionate about advancing quantum sensing applications and integrating novel technologies to meet industry needs.