For example, the following remote sensing scenarios can be implemented using a fiber optic sensor:

- Sensing mean part

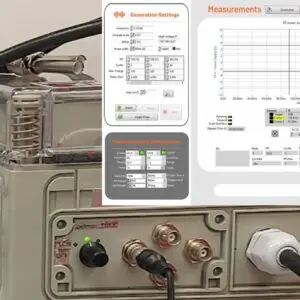

- The fiber input can be optically coupled with different electro-optical sensors (that convert electrical signals to optical)

- The fiber input itself can be an optical sampling “window” to mapping a light source intensity

- Special fibers can undergo changes (e.g., refraction indexes) under the influence of the measured phenomena (e.g., temperature-dependent changes) providing sensing mean by itself

- Sampling mean part

- The fiber output coupled with a light sensor (e.g., photodiode) provides a sampling mean

Optical Fiber Working Principal

The conventional optical fiber comprises a core and a cladding material surrounding it; the core and the cladding have different refractive indices (the core’s refractive index is higher). The light beam launched into a fiber travels through the core; the beam propagation angles must be smaller than the critical angle of a fiber’s core-cladding interface. The fiber’s Numerical Aperture (NA) defines the acceptance angle of the light cone entering the fiber to be within a critical angle of the core-cladding interface.

For example, for a glass core fiber and NA=0.22 the acceptance angle is approximately 25.4 degrees. The light beam that has passed through the fiber exits in a cone according to its NA.

The fiber cores can be of the following types:

- Plastic: The plastic-fiber core contains one or more acrylic-resin (PMMA synthetic polymer) fibers 0.25 to 1 mm in diameter. Their cost-effectiveness and flexibility make the plastic-core fibers a reasonable choice in many areas, including fiber optic sensors.

- Glass: The glass core is usually made from doped silica whereas the dopants control the core refractive index. Can be used in high temperatures environment.

From here:https://www.keyence.com/ss/products/sensor/sensorbasics/fiber/info/index.jsp