Introduction: The Science of Laser Measurements and Why They Matter

Laser technology has revolutionized countless fields, from precision manufacturing and medical surgery to telecommunications and scientific research. For physicists, researchers, and laser enthusiasts – or “laser lovers” – understanding the intricacies of laser performance and measurement is both a passion and a necessity. Laser lovers are united by their commitment to precision, performance, and innovation, qualities that are vital in the world of lasers, where the smallest fluctuations in beam quality or power output can have significant impacts on results.

Laser measurement is an essential practice in the development, production, and quality control of laser systems. At its core, laser measurement provides critical data on a laser’s characteristics, ensuring it meets the specifications required for its intended application. This data allows scientists and engineers to validate and refine laser performance, contributing to advancements in fields as diverse as quantum optics, material processing, and biomedical devices.

A well-calibrated and comprehensive measurement system is indispensable for anyone working with lasers. Without accurate measurements, it’s impossible to guarantee the quality, safety, or reliability of a laser. Laser measurement encompasses several key parameters: spatial (beam profile), temporal (pulse shape and duration), and energy/power. Each of these parameters tells a part of the laser’s story and is crucial for ensuring it operates at peak performance. Whether you’re a manufacturer preparing a laser for shipment or a researcher relying on precise laser output for experiments, laser measurements are your assurance of quality and consistency.

For laser lovers looking to dive deeper into the art and science of laser testing, IZAK Scientific’s TriBeam Precision offers an all-encompassing solution. Read on to learn how these essential laser measurements can be achieved with a single system that combines spatial, temporal, and energy/power analysis.

What Laser Measurements Matter in Production and Quality Control?

To ensure a laser is functioning correctly, there are three critical measurements you must consider:

-

Spatial Measurements (Beam Profile): The shape, size, and intensity distribution of the laser beam across its cross-section are crucial. Variations in beam profile can affect precision and power distribution, which is particularly vital for applications like cutting, engraving, or medical procedures.

-

Energy and Power Measurements: Knowing a laser’s power or energy per pulse is essential for understanding its output and ensuring it’s within the acceptable range. This measurement is critical for lasers used in applications where energy consistency directly impacts results, like laser welding or medical treatments.

-

Temporal Measurements (Pulse Shape and Repetition): For pulsed lasers, pulse shape and temporal behavior are important. Any inconsistencies can impact applications that rely on specific pulse durations or repetition rates, such as pulsed laser ablation or lidar systems.

These measurements ensure that each laser meets the required specifications, performs safely, and remains effective over its intended lifespan.

Enter TriBeam Precision: A Comprehensive Laser Testing Solution

For companies looking to streamline and enhance their laser testing processes, IZAK Scientific’s TriBeam Precision offers an all-in-one solution. TriBeam Precision is designed to handle all three critical laser measurements – spatial, temporal, and energy/power – in parallel, simplifying the acceptance testing process for laser manufacturers and users alike.

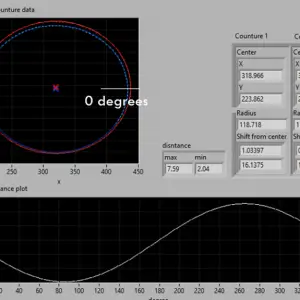

Watch the Demo: The video below showcases the TriBeam Precision in action, measuring laser beam profile, power or energy per pulse, and temporal pulse shape simultaneously. This ability to perform comprehensive measurements in one system is a game-changer, enabling quick and accurate testing without needing multiple devices or complex setups.

Key Features of TriBeam Precision

-

Beam Profiling: TriBeam Precision provides high-resolution 2D and 3D beam analysis, allowing users to precisely measure the laser’s spot size, shape, and intensity distribution. Whether you’re working with single or fractional laser beams, TriBeam Precision can provide accurate spatial data, ensuring that your laser meets quality standards.

-

Calibrated Power and Energy Measurement: With a calibrated power meter and energy per pulse measurement, TriBeam Precision gives you the confidence that your lasers are performing within the required power range. The system can handle power measurements from low to high levels, accommodating various laser types and applications.

-

Pulse Shape Analysis: For pulsed lasers, temporal measurement is vital. TriBeam Precision includes a fast-response detector to capture the pulse shape and analyze the temporal profile, ensuring that pulse duration, frequency, and shape are consistent and within spec. This capability is especially useful for quality control in production lines for Q-switched and mode-locked lasers.

-

Flexible Wavelength Range: TriBeam Precision supports multiple wavelength ranges – from UV-VIS-NIR to SWIR and LWIR – making it versatile enough to handle different types of lasers. This flexibility allows companies to test a wide array of lasers with a single device.

-

Multiple Configurations for Different Applications: TriBeam Precision is available in various configurations to accommodate different beam sizes and power levels, from low-power lasers for laboratory research to high-power industrial lasers for cutting and welding.

Why Laser Testing on Production Lines Is Critical

For companies manufacturing lasers, an acceptance test before shipping is essential. This test is the final quality check to ensure that the laser performs as expected, adheres to regulatory requirements, and meets customer specifications. By performing thorough testing at the production stage, manufacturers can identify any issues before the product leaves their facility, reducing the risk of malfunctions, returns, and dissatisfied customers.

On the other hand, companies using lasers in their production processes also benefit from regular testing. Ensuring that their lasers are performing correctly allows them to avoid unexpected downtime, maintain high standards, and optimize their operations.

Added Value for Laser Lovers: Connecting Performance with Passion

At IZAK Scientific, we know that laser enthusiasts, or “laser lovers,” are passionate about precision, performance, and innovation. The TriBeam Precision system was developed to address these values, providing laser aficionados and professionals with a tool that embodies reliability and accuracy. With TriBeam Precision, companies can focus on analyzing laser data rather than spending time acquiring it, echoing our motto:

“Spend your time analyzing data, not working out how to acquire it!”

By making laser testing simple, intuitive, and comprehensive, TriBeam Precision enables laser lovers to delve deeper into their work with confidence, knowing that every measurement is precise and trustworthy.

Why Choose TriBeam Precision for Your Laser Testing Needs?

TriBeam Precision is more than just a testing tool; it’s a comprehensive solution designed for ease of use and versatility. With TriBeam Precision, you gain:

- Efficiency: Perform three measurements simultaneously, reducing testing time and increasing throughput on production lines.

- Accuracy: Calibrated measurements across all three domains (spatial, temporal, energy/power) ensure compliance with quality standards.

- Flexibility: Suitable for a variety of laser types and applications, from low-power laboratory lasers to high-power industrial lasers.

- Reliability: By using a single device for comprehensive testing, TriBeam Precision reduces setup errors and ensures consistent, repeatable results.

Closing Thoughts

For companies invested in laser quality, IZAK Scientific’s TriBeam Precision provides an innovative and reliable way to ensure performance and safety. Whether you’re shipping lasers to clients or relying on them in your production processes, this all-in-one solution allows you to maintain the highest standards of quality and consistency.

Embrace the power of accurate, calibrated measurements with TriBeam Precision, and experience a new level of confidence in your laser testing processes.

Tzachi Sabati

CEO, IZAK Scientific

Physicist specializing in photonics and quantum technologies, with deep expertise in quantum sensors and advanced optical systems. Leads the Advanced Quantum Lab course at the Technion, bridging academic excellence with industry innovation. At IZAK Scientific, provides cutting-edge photonics-based solutions, developing customized inspection and sensing systems for R&D and production. Passionate about advancing quantum sensing applications and integrating novel technologies to meet industry needs.