Maintaining the cleanliness of workplaces is essential. The food and food processing industries are not an exception. In fact, they need the utmost hygiene to make contamination-free food products. Only those food products that are free from pathogens can have a longer shelf-life. If the food products are sold with reduced shelf-life, the quality becomes a question. Ultimately, this affects the profit/sales of the company.

Among various food processing industries, meat processing takes the top spot. This is due to the increasing demand for processed meat. Ensuring to follow a stringent set of protocols, standards, and quality checks has become mandatory in these industries and meat processing plants. At every stage of operation, sanitation has to be retained. All food processing industries have to satisfy the FDA standards and the FDA Food Safety Modernization Act (FSMA).

Why Choose UV Light Disinfection For Meat Processing?

UV light, with its germicidal properties, destroys the microorganisms, such as bacteria, viruses, fungi, and mold. When the nucleic acids of these microbes absorb the UV light, it forms pyrimidine dimers. These dimers prevent the microbial cells from proliferating or replicating. Research studies have proved the effectiveness of UV light in inactivating bacteria, viruses, and molds present in the air, water, and surfaces of the food processing industries.

Advantages of deploying the UV light disinfection in meat processing industries include:

- Reliable disinfection approach

- Economical disinfection of bulk products/equipment

- 99.99% killing of microbes

- Does not affect the final product (processed meat)

- Treats all meat processing equipment and machinery

- Prohibits the use of chemical disinfectants

- Increases the shelf-life of the processed meat

- Higher quality products and services

- Increases brand value and profitability

- Safer working conditions for employees and labors

Applications of UV Light in Meat Processing

UV light has several applications in the meat processing industry. Some of the important and efficient applications include:

- Packaging rooms

- Sausage or meat production

- Brine chillers

- Carcass rinsing

- Slaughter rooms

- Pickle injectors

- Bacon slicing

- Conveyor belt

- Water treatment & effluent

- Meat marinade

- Viscera cleaning

- Fresh meat workspaces

- Cooling towers

From the materials used for meat processing to the final meat products, everything can undergo UV light disinfection. This enables the whole workspace to remain free from contaminations and friendly to produce high-quality processed meat.

UV Disinfection Approaches Exclusive to Meat Industry

UV light has different approaches to the meat industry. The most useful approaches include UV light sanitizer and UV light disinfection chamber.

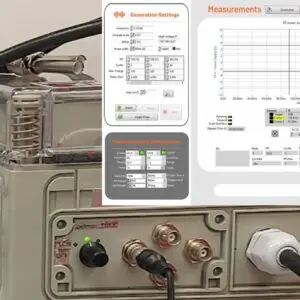

(i) UV Light Sanitizer

A UV light sanitizer can help you with disinfecting work surfaces, materials, carcass rinsing tubes, industrial knives and blades, carcass trays, processed meat holders, and conveyor belts. These sanitizers are deployed either in the form of portable stands or fixtures on the wall based on the need and application.

Check out the best selling UV light sanitizers!

(ii) UV Light Disinfection Chamber

UV disinfection chambers are largely helpful in bulk meat processing. When industries aim at processing large quantities of meat, they need large disinfection chambers.

Check out the most recommended UV disinfection chamber!

Tzachi Sabati