IZAK Scientific specializes in fiber optics inspection, showcasing our expertise in this area on this page. We highlight the measurement systems utilized for optical fiber testing, crucial in the custom fiber production process, including tasks such as cleaving fiber tips, measuring pitch, and determining fiber height. Another key development of ours caters to fiber optics communication, where we’ve engineered a system to measure and test fiber bundles, enhancing both research capabilities and manufacturing quality.

We also introduce two systems designed for delivering high-power laser energy through optical fibers for medical tissue treatments. One system assesses fiber transmission post-production and pre-delivery, ensuring quality before reaching the customer. Another focuses on aligning fiber connectors with precision, incorporating a 5-7 pixel beam profiler for imaging high power narrow laser beams within SMA connectors, essential for active alignment during assembly.

Our optical fiber ferrule inspection tester, crucial for fiber production, ensures the highest quality and reliability of optical fiber ferrules. It includes:

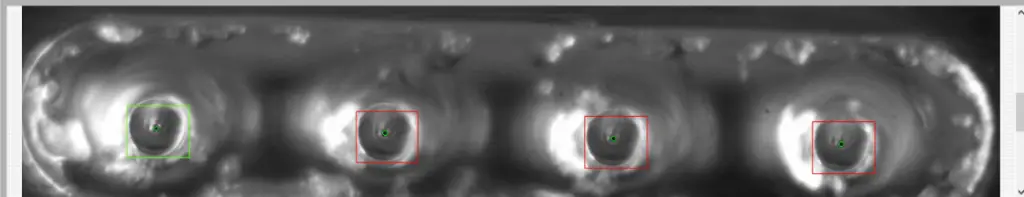

1. High-Resolution Imaging System: Uses advanced cameras coupled to microscopes for detailed inspection of the fiber surface and cross-section, identifying defects and inconsistencies.

2. Automated Image Analysis Software: Employs image processing algorithms for defect detection and parameter measurement, essential for quality assurance.

3. Real-time Monitoring and Feedback: Offers instant quality feedback, crucial for optimizing the production process and minimizing waste.

4. Data Logging and Reporting: Captures detailed inspection data for quality control, process optimization, and compliance purposes.

5. Customizable Testing Parameters: Adapts to various fiber types and standards, ensuring versatile application across production needs.

6. Robust Design and User-Friendly Interface: Built to endure production environments with an intuitive interface for ease of use.

7. Precision Alignment Mechanisms: Facilitates accurate fiber positioning for consistent inspection results, with automated focus adjustments enhancing reliability.

Applications range from quality control and process optimization to supporting research and development of new fiber types.

Watch a short demonstration:

Fiber Cleaving Tester

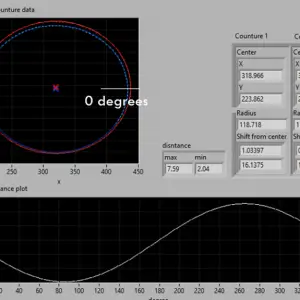

We also feature a system for inspecting fiber optic post-cleaving, utilizing image processing for precise measurements crucial in optical communications.

Overview of the System

The testing measurement system developed for inspecting fiber optic post-cleaving is an advanced tool that plays a crucial role in ensuring the quality and reliability of fiber optic connections. This system is particularly designed for high-volume production, where speed, accuracy, and consistency are paramount.

Benefits

· Enhanced Quality Control: Precise measurements and consistent application of inspection criteria lead to improved quality of fiber optic connections, crucial for high-speed optical communications.

· Data-Driven Insights: Accumulated inspection data provides insights into production processes, guiding decisions that enhance product quality and operational efficiency.

· Increased Production Efficiency: Automating the inspection process reduces inspection time per ferrule, enabling higher throughput without compromising on quality.

· Reduced Waste: Immediate detection and correction of defects lower the rate of rework and waste, contributing to cost savings and more sustainable production practices.

The testing measurement system developed for post-cleaving inspection of fiber optic ferrules represents a significant advancement in the production of optical communications components. By leveraging high-quality imaging and sophisticated image processing algorithms, this system delivers unparalleled accuracy and efficiency in ferrule inspection, setting new standards in quality control for fiber optic manufacturing.

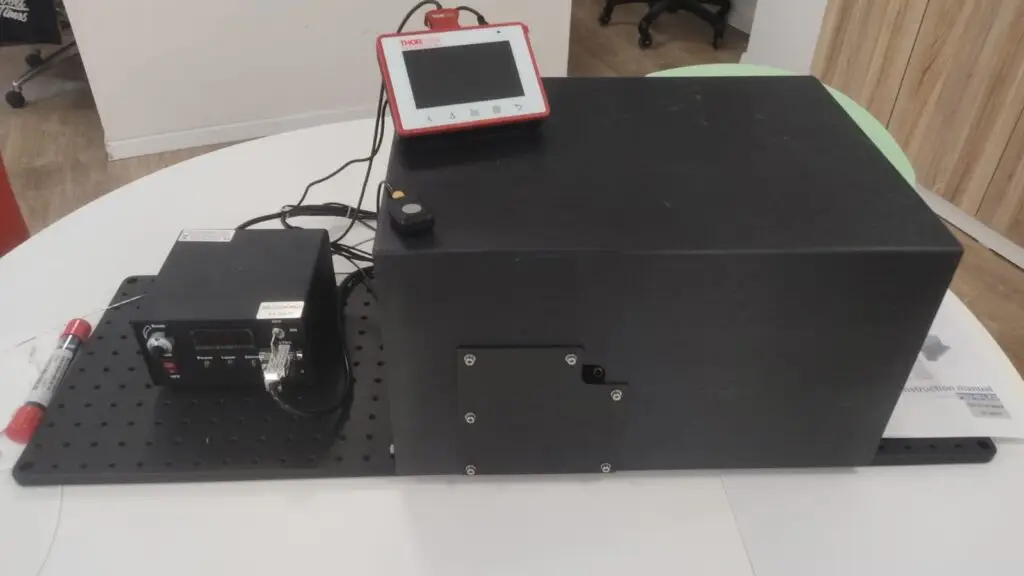

Fiber Transmission Tester System for High Power Lasers

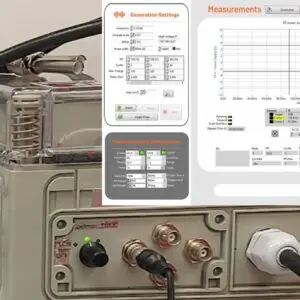

We designed and delivered for measuring high-power laser beams delivered via optical fiber showcases photonics engineering example to accurately assess fiber transmission efficiency. This fiber transmission measurement system is meticulously crafted to accommodate high-power applications, ensuring precise evaluation of laser power transmission through optical fibers. Below is an in-depth look at its features and functionalities:

Ensuring Precise Fluence in Medical Laser Devices – the main tester objective

In the realm of laser-based medical devices, achieving the correct fluence—defined as the optical energy density impacting the tissue—is paramount. The primary objective of the fiber transmission tester is to ensure this precision. Insufficient transmission results in reduced fluence, rendering the treatment less effective on the targeted tissue. Conversely, transmission exceeding the specified limits can lead to excessively high fluence, posing risks of tissue damage, burns, or more severe outcomes. Thus, the tester plays a critical role in balancing the transmission to achieve optimal fluence, ensuring both the efficacy and safety of laser treatments in medical applications.

Dual Optical Path Configuration

Two Optical Paths: The core functionality of this system lies in its dual optical path configuration, which allows for the measurement of laser power in two distinct manners. This setup is essential for accurately determining the transmission efficiency of optical fibers under different conditions.

Bypass Optical Path: Alongside the main measurement path, there is a bypass path. This secondary path is utilized to compare the direct laser power without passing through the fiber, serving as a reference or control measurement to ensure accuracy.

Switchable Paths: The transition between the main optical path and the bypass path is seamlessly controlled by a simple button click. This user-friendly design enables quick switching during testing procedures, facilitating efficient measurement processes.

Measurement and Calculations

Laser Power Measurement: The system is equipped with sensitive and calibrated detectors capable of accurately measuring high levels of laser power. These detectors are calibrated to ensure precision in readings, which is critical for high-power laser applications.

Fiber Transmission Calculations: By comparing the laser power measurements from both the main and bypass paths, the system calculates the transmission efficiency of the optical fiber. This calculation is vital for assessing the performance of the fiber in transmitting high-power laser beams.

Applications and Benefits

High-Power Laser Applications: This system is tailored for environments where optical fibers are used to deliver high-power laser beams, such as in medical devices, industrial machining, and telecommunications.

Quality Assurance: By providing precise measurements of fiber transmission efficiency, the system plays a crucial role in quality assurance processes for optical fiber products. Manufacturers can identify and address any discrepancies in transmission efficiency, ensuring that the fibers meet the required specifications for high-power applications.

For laser-based medical devices, maintaining precise fluence is critical for treatment efficacy and safety. The fiber transmission tester ensures optimal energy density on tissue, preventing insufficient or excessive transmission that could lead to ineffective treatments or tissue damage, respectively.

Research and Development: The detailed data gathered by this system can also support research and development efforts, enabling the exploration of new fiber materials, designs, and coatings to enhance transmission efficiency.

Conclusion

The development of this fiber transmission measurement system marks a significant advancement in the testing and quality assurance of optical fibers for high-power laser applications. Its dual optical path configuration, combined with the ability to accurately measure and calculate fiber transmission efficiency, provides a robust tool for manufacturers, researchers, and engineers working with advanced optical fiber technologies.

Our multi-channel power meter is engineered for the precise measurement of high-power laser beams, especially those of a narrow nature. These beams often reach peak powers in the tens of kilowatts range, with diameters as small as approximately 100 microns. The system specializes in the beam profiling of such high-irradiance beams.

Equipped with a custom-designed narrow beam adapter probe, the power meter excels at capturing images of slim beams across a resolution of 5-7 pixels. This high level of detail is crucial for accurately profiling narrow beams, necessary for applications that demand exact beam alignment and focus.

This technology proves especially useful in both research and industrial settings, where precise characterization of beam width and distribution is crucial for optimal performance.

Applications in Alignment and Focus:

A primary application of this advanced measurement tool is in the alignment of SMA connectors. The power meter’s precise measurement and profiling capabilities are invaluable for achieving perfect alignment, essential for maximizing efficiency in fiber optic transmission.

Furthermore, the device is highly effective at evaluating the focus on the surfaces or interiors of fiber ferrules. This functionality is critical not only for quality assurance during the manufacturing of fiber optics but also for routine maintenance and troubleshooting within operational systems. The power meter thus offers essential insights into the focusing properties of fibers, ensuring the highest standards of quality and performance in fiber optic applications.