Many industries make use of lasers nowadays. Through the use of lasers, numerous applications can be improved upon. However, there are specific criteria that can improve your selection process.

Lasers came about decades ago, and in that time virtually every industry has benefited from them. With so many applications from optics to electronics and from communications to nearly every possible technical field, lasers are extremely useful. Consumer products including DVD players have lasers, and even surgery benefits from the use of the laser.

There are four major categories that summarize the types of lasers in common practice. There are fiber lasers, gas lasers, laser diodes and solid state lasers. Naturally, each type of laser has a specific circumstance in which it is best used. Since every type of laser has its unique advantages and drawbacks, each one is best for a particular purpose.

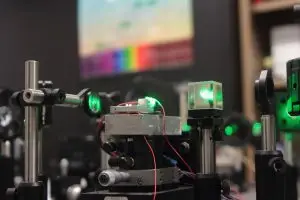

The earliest types of lasers were primarily of the solid state variety. Usually, this consisted of ruby lasers, the first kind developed. This came from an early design called a ruby maser. The name is actually inspired by the material, as solid state lasers make use of a crystal for use as the gain medium. There is a great deal of stability in solid state lasers, which makes them excellent controls in the laboratory and for testing. In general, their efficiency is low (usually a few percent), which can impose limitations but not overly large ones. Perhaps their largest drawback is their relatively small range of potential wavelengths and fairly narrow wavelength tuning. One of the more useful varieties is the diode-pumped solid state or DPSS laser. This allows excitement through a diode laser instead of the industry standard Xenon flash lamp.

Fiber lasers use elements in the fibers themselves allow for stimulated emission. A Bragg grating and inscription in the fiber at each end provides the reflection that amplifies the light instead of using mirrors that form a cavity. Fiber lasers are the most useful type for fiber optic systems, which makes them ideal for telecommunications applications. The most common type of fiber amplifier in these industrial applications is the erbium-doped fiber amplifier or EDFA.

The mail medium of a gas laser is a gas. This allows for higher gains that do not require amplifiers, as well as a higher level of power output and stability with a smaller range of wavelength drifting. However, there is the disadvantage that the gas needs to be in a sealed chamber.

By far the most common type of gas laser uses CO2, particularly for surgical and other medical procedures. HeNe lasers also have uses in the field of spectroscopy, interferometry and to align virtually anything regardless of its field. There are many wavelengths that extend into the ultraviolet and infrared spectra through the visible. The efficiency is moderate at between five and twenty percent, but the stability and reliable of a gas laser is great.

The laser diode is another category that deserves note. Such devices are p-n or p-i-n junction diodes that put forth light during the application of electrical current. There are a few subtypes of laser diode, among them are surface emitting such as a vertical cavity surface emitting laser or VCSEL and the edge emitting variety. In cases other than VCSEL the beam shape of a diode laser is elliptical, which diverges rapidly along the vertical direction of the stack due to the thin layer of material along that dimension (slow and fast axis). A cylinder is used as a collimating lens, though a prism pair can also be used to shape the beam to use in its different functions. The VCSEL is a newer type of development that does not have this type of problem. These laser diodes may use either direct contact or air to couple to optical fibers.

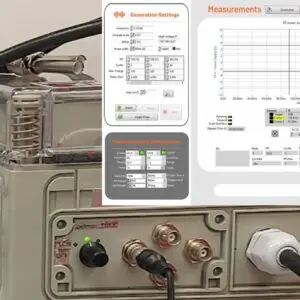

The diode laser has an extra high conversion efficiency, which can range between 20 percent and 70 percent. This depends on what current is driving the laser and the materials used for the process. When heat dissipation is a factor or power consumption must be carefully controlled, diodes are excellent and low cost lasers. The drive current is what informs the output power. Like a gas laser, a diode laser comes in many different wavelength options, but unlike gas lasers temperature changes cause substantial wavelength drift with diode lasers.

Electrical circuitry is where diode lasers are at their best, as they integrate easily into circuits. With soldering, a circuit board or design software can integrate or simulate diode lasers easily. Also, there is no need for external shutters or acoustic modulators, since the drive current can change the modulation. The inverse of a diode laser works well as a photodetector.

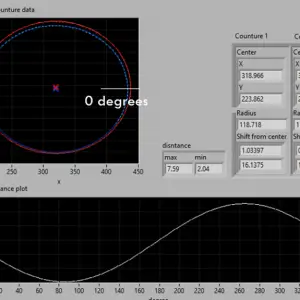

The choice of a particular laser for any given application is to assess the most critical aspects of the system in question. The drift of wavelength is important, particularly when the emitted light can change because of a small instability. Motion detection and illumination carry no consideration for wavelength, but in some cases drift can matter a great deal. Particularly important is the use of specific wavelengths in interferometric measurement to gauge surface texture or thin films or coatings, where a wavelength error can lead to an overall measurement area. In cases where safety is paramount, using the lowest possible level of power is useful.

A product can be made or broken based on which type of laser is used. There are many options available, and choosing the right one is always possible. Advice on the particular type of laser you need is available, and thorough testing can be performed.

Tzachi Sabati

CEO, IZAK Scientific

Physicist specializing in photonics and quantum technologies, with deep expertise in quantum sensors and advanced optical systems. Leads the Advanced Quantum Lab course at the Technion, bridging academic excellence with industry innovation. At IZAK Scientific, provides cutting-edge photonics-based solutions, developing customized inspection and sensing systems for R&D and production. Passionate about advancing quantum sensing applications and integrating novel technologies to meet industry needs.