In response to the growing demand for reliable and high-performance LED systems, IZAK Scientific developed a cutting-edge LED and screen inspection system for MKS company. This system ensures that each product meets stringent quality standards before shipment. By leveraging the scientific principles of radiometry, the system precisely measures LED performance, while advanced software provides real-time monitoring and detailed quality assurance reporting. In this article, we explore the importance of QA, the role of radiometry in LED measurement, and the capabilities of the system developed for MKS.

Overview of the LED and Screen Inspection System

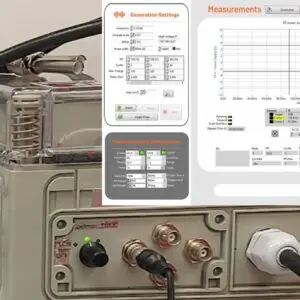

At IZAK Scientific, we have engineered a sophisticated LED and screen inspection system designed to ensure that each product meets stringent quality standards before it is shipped. The system features a closed-cover design, providing a controlled environment for testing each Unit Under Test (UUT). Each UUT contains approximately twenty LEDs, each capable of operating at different wavelengths, along with a seven-digit screen displaying critical information.

The system incorporates Optical Character Recognition (OCR) to verify the accuracy of the displayed text and evaluates each LED’s performance by checking whether it emits light at the expected wavelength and intensity. The results are compiled into a detailed report essential for quality assurance processes.

Key Features of the System

The LED and screen inspection system is designed with several features that optimize the inspection process:

-

- Closed-Cover Design: Ensures a consistent and controlled testing environment by keeping the UUT isolated during testing.

-

- Multi-Wavelength LED Testing: Each LED is tested individually to confirm that it emits light at the correct color and intensity.

-

- OCR Text Recognition: The OCR system checks the accuracy of the text displayed on the seven-digit screen, flagging any discrepancies.

-

- Real-Time Monitoring: The software interface offers live monitoring of LED color status and OCR results, allowing for immediate issue detection and correction.

-

- API and Automation: A minimalistic API with commands for enabling/disabling the detection system and performing tests allows for easy integration into production workflows.

-

- Output and Reporting: Detailed output files are generated after each test, including data on LED color, LED ID, and recognized text, serving as a vital record for quality assurance.

Real-Time Monitoring and Software Interface

A key aspect of the system is its advanced software, designed to provide real-time monitoring and data analysis. The software displays live data on each LED’s status, the results of the OCR text recognition, and the overall progress of the testing process. This real-time capability is crucial for ensuring that any issues are promptly identified and addressed, preventing defective products from progressing further in the production process.

The user-friendly interface simplifies the operation of the system, enabling operators to focus on critical aspects of quality assurance without being bogged down by complex controls. The software’s ability to automatically compile detailed reports further enhances the efficiency of the QA process, ensuring that all necessary data is captured and can be analyzed for trends or recurring issues.

Case Study: Implementation at MKS

Our LED and screen inspection system was recently

implemented at MKS, a company that places a high value on rigorous QA

inspections before shipping its products. By integrating our system into their

quality control processes, MKS ensures that their LED modules and screen

displays meet the highest standards of performance and reliability before they

reach their customers. The system’s real-time monitoring capabilities and

detailed reporting tools have become essential elements of MKS’s QA workflow,

helping them maintain their reputation for excellence.

Scientific Background: Radiometry in LED Measurement

The accuracy and reliability of LED measurement are

underpinned by the principles of radiometry—the science of measuring

electromagnetic radiation, including visible light. Radiometric quantities,

such as radiant flux, radiant intensity, irradiance, and radiance, are

essential for characterizing the optical performance of LEDs. These principles

ensure that the light output of LEDs is accurately measured and that the LEDs

perform as expected in their intended applications.

For a more in-depth exploration of radiometric principles

and their application in LED measurement, please refer to our detailed article

on radiometry available on the IZAK Scientific website.

The Importance of Quality Assurance in LED Inspection

Quality assurance (QA) is essential for ensuring that

LED systems perform reliably under real-world conditions and meet performance

standards before delivery. Here’s why QA matters:

- Ensuring

Product Reliability

QA testing identifies issues such as malfunctioning LEDs, incorrect wavelengths, or inaccurate text displays. This process ensures reliable performance, reducing the risk of failures in the field. - Preventing

Costly Recalls

Thorough testing prevents defective products from reaching the market, minimizing the risk of recalls due to issues like incorrect LED color or text recognition errors. This early detection saves both time and money while maintaining customer trust. - Maintaining

Consistent Quality

QA ensures uniform performance across all products, eliminating variations that could harm the brand’s reputation. Consistency is key to maintaining product integrity and customer confidence. - Data-Driven

Improvements

The system generates valuable data from each test, helping identify recurring issues and drive improvements. This leads to higher overall product quality and better process efficiency.

In the highly competitive LED

market, ensuring the quality and reliability of products is more important than

ever. Our LED and screen inspection system represents a significant advancement

in QA technology, providing manufacturers with the tools they need to verify

product performance before shipment. By integrating advanced radiometric

principles with cutting-edge software for real-time monitoring and reporting,

the system helps prevent defects, ensure consistency, and ultimately improve

customer satisfaction.

Whether you are a physicist

interested in the scientific principles of LED measurement, an engineer focused

on the practical aspects of product design, or a quality assurance manager

responsible for maintaining product standards, this system offers a comprehensive

solution for ensuring the highest levels of quality in LED manufacturing.

Tzachi Sabati

CEO, IZAK Scientific

Physicist specializing in photonics and quantum technologies, with deep expertise in quantum sensors and advanced optical systems. Leads the Advanced Quantum Lab course at the Technion, bridging academic excellence with industry innovation. At IZAK Scientific, provides cutting-edge photonics-based solutions, developing customized inspection and sensing systems for R&D and production. Passionate about advancing quantum sensing applications and integrating novel technologies to meet industry needs.